Complex Moving Geometries

Minimize artificial viscosity

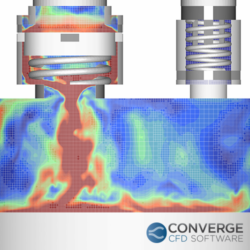

When simulating moving geometries, a common approach is to use a mesh that moves with the geometry. A moving mesh creates additional numerical (artificial) viscosity that smears features of the solution and reduces the accuracy of the calculation. In CONVERGE, however, the mesh is stationary so as to minimize this artificial viscosity. CONVERGE contains optimized automatic mesh generation algorithms that accommodate the geometry motion by creating a new mesh at each time-step. The result is higher accuracy.

A Cartesian mesh for complex geometries

One approach to meshing complex geometries is to use a non-Cartesian mesh (e.g., tetrahedral elements in 3D). When a CFD simulation uses this type of mesh in conjunction with a moving geometry, the cells become distorted and may have defects. Such defects may result in instabilities that prevent the simulation from reaching an answer. CONVERGE’s Cartesian mesh is numerically stable, which reduces the time you spend diagnosing erroneous simulation results.

A challenge with a conventional Cartesian mesh is that the geometry is simplified either by a stair-stepped approach or by making single planar cuts on boundary cells. These processes reduce the accuracy of the calculation. In CONVERGE, however, this is not an issue. CONVERGE employs a unique cut-cell approach that perfectly represents the underlying geometry as provided by the user. Another challenge with a Cartesian mesh is resolving the boundary layer of a boundary that is not aligned with the mesh. For boundary layer calculations, CONVERGE’s Adaptive Mesh Refinement feature can increase the mesh resolution in the vicinity of the boundary such that the cell size is sufficient to predict boundary layer effects.