Exhaust Aftertreatment

Importance

Aftertreatment systems are critical to ensure emissions from engines and power generation equipment comply with environmental standards. CFD simulations can be used as part of a rapid prototyping process to design systems that reduce NOx, CO, and particulate matter emissions with maximum efficiency and minimal maintenance costs. Three of the main challenges in aftertreatment system design are maximizing the uniformity of flows upstream of catalysts, mitigating urea deposition, and increasing the efficiency of particulate filters while maintaining a low pressure drop. CONVERGE can help you overcome all of these challenges. And, because it eliminates user meshing and incorporates simulation acceleration techniques like the fixed flow method and the conjugate heat transfer model with super-cycling, CONVERGE quickly produces results that are consistent across runs.

Maximize Uniformity

The uniformity of the ammonia injection upstream of the SCR catalyst brick is paramount when it comes to the size, cost, and NOx reduction efficiency of an aftertreatment system. CONVERGE can predict the production and transport of different species such as NH3 and HNCO upstream of the catalyst in a time-efficient manner. Design variables such as mixer location, perforated plates, and pipe configurations can easily be modified to understand their impact on uniformity and system pressure drop without re-meshing. CONVERGE offers commonly used urea decomposition approaches, including molten-solid and multi-component, so you can choose the appropriate option for your case. Furthermore, you can tune the reaction coefficients if test data are available. CONVERGE’s fixed flow method and time-averaging enable uniformity simulations for systems with pulsed spray and transient films.

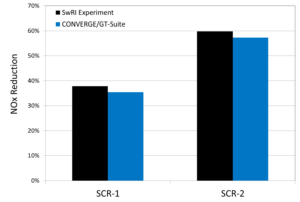

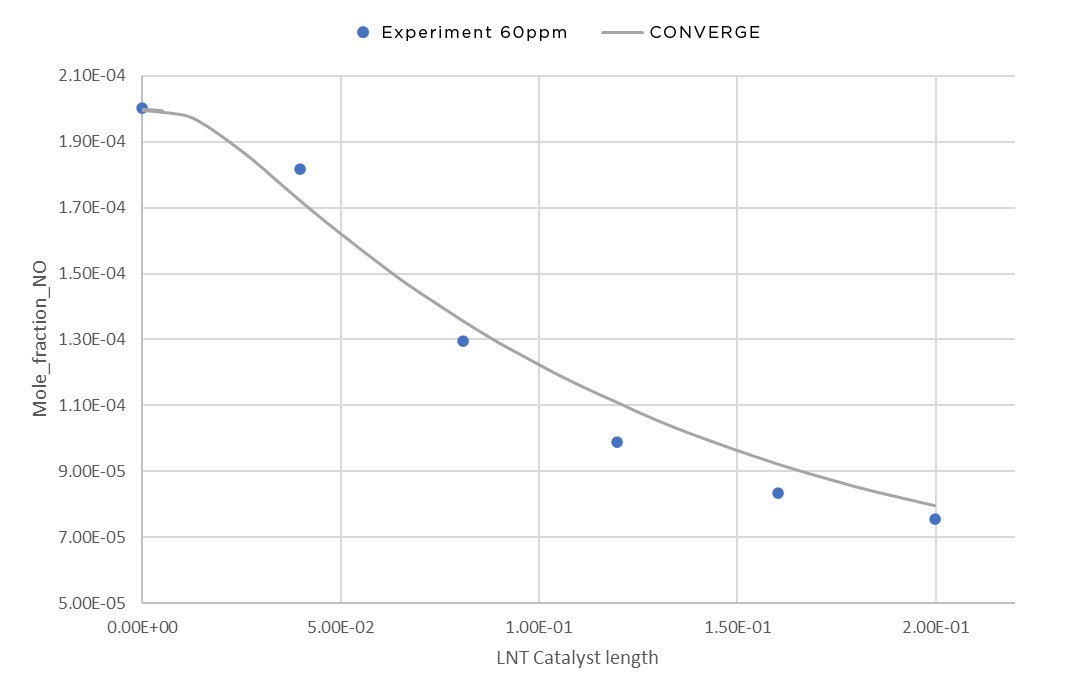

Surface Chemistry

CONVERGE can solve the surface chemistry for a variety of aftertreatment catalyst devices, such as diesel oxidation catalyst (DOC), selective catalyst reduction (SCR), and lean NOx trap (LNT), among others. CONVERGE offers two types of surface chemistry modeling. The region-based surface chemistry solver allows users to model the catalyst as a porous medium and solves the surface chemistry in each computational cell of the porous medium. The boundary-based surface chemistry approach solves only the surface chemistry on the boundaries that construct the catalyst channels. CONVERGE can also couple with 1D surface chemistry tools such as GT-SUITE. The non-uniform flow profile predicted by CONVERGE can be imported into the 1D surface chemistry tools to solve the surface chemistry.

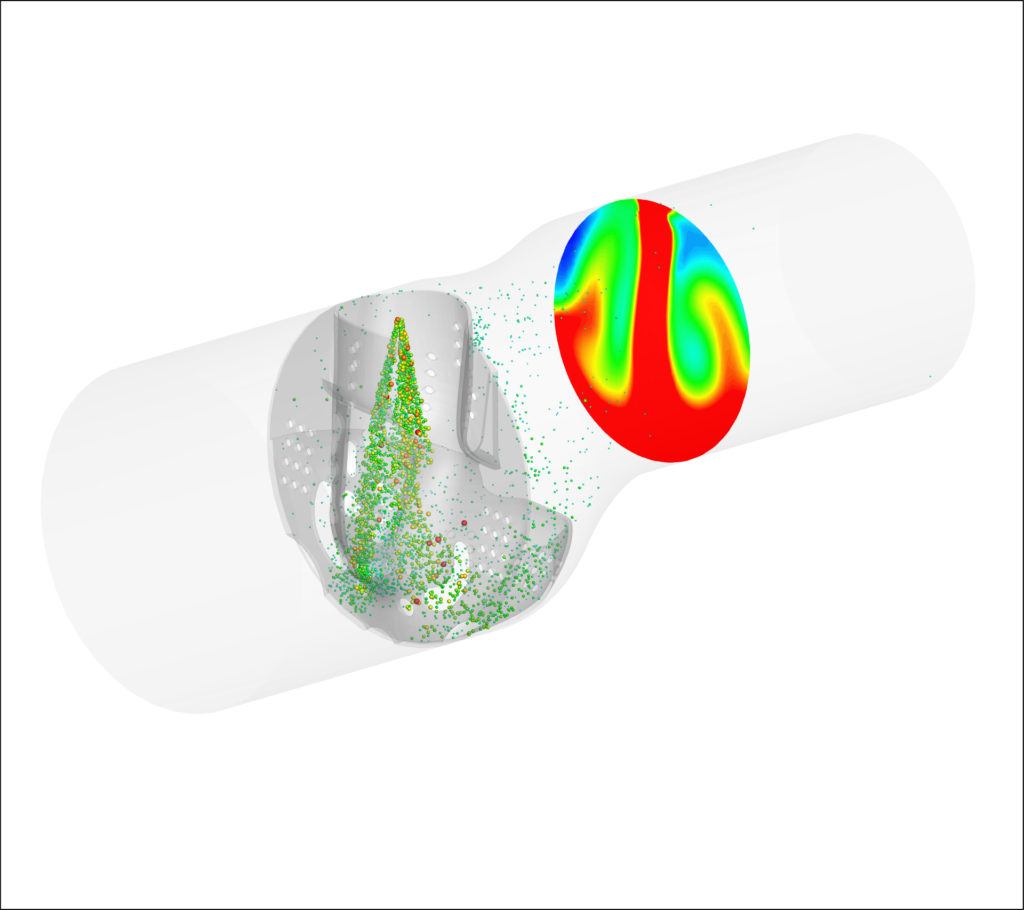

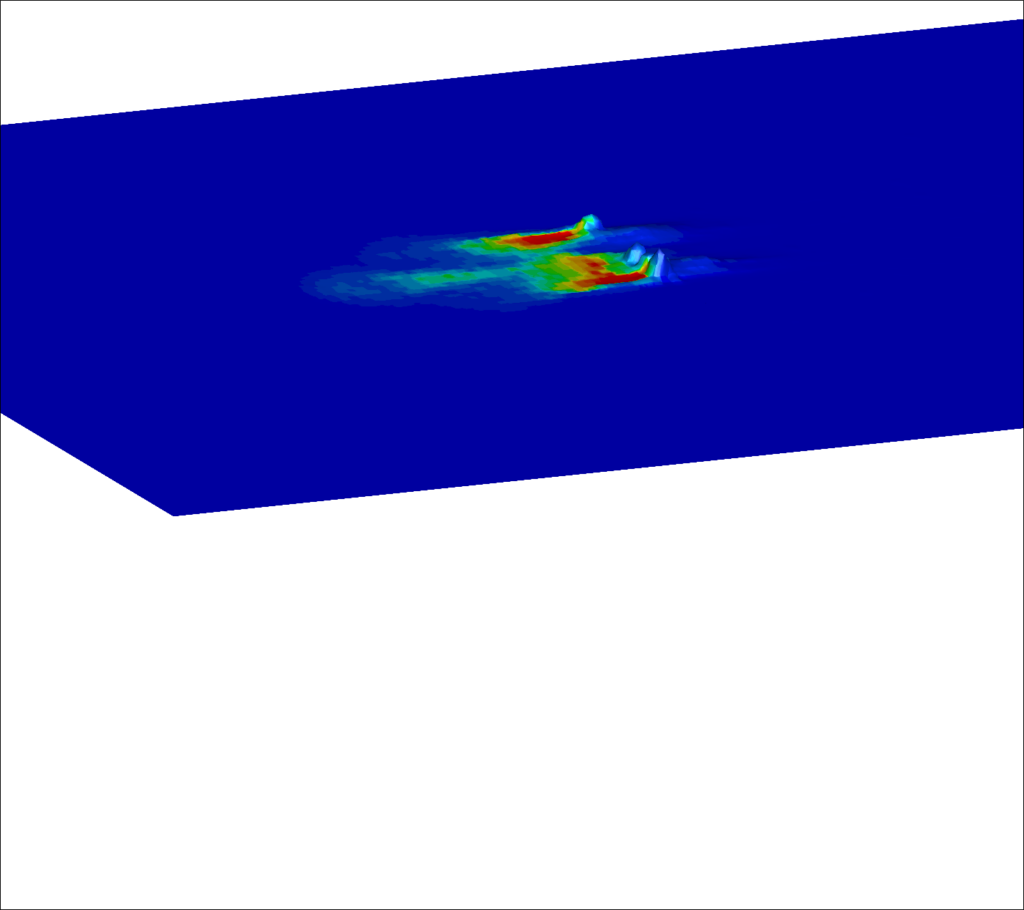

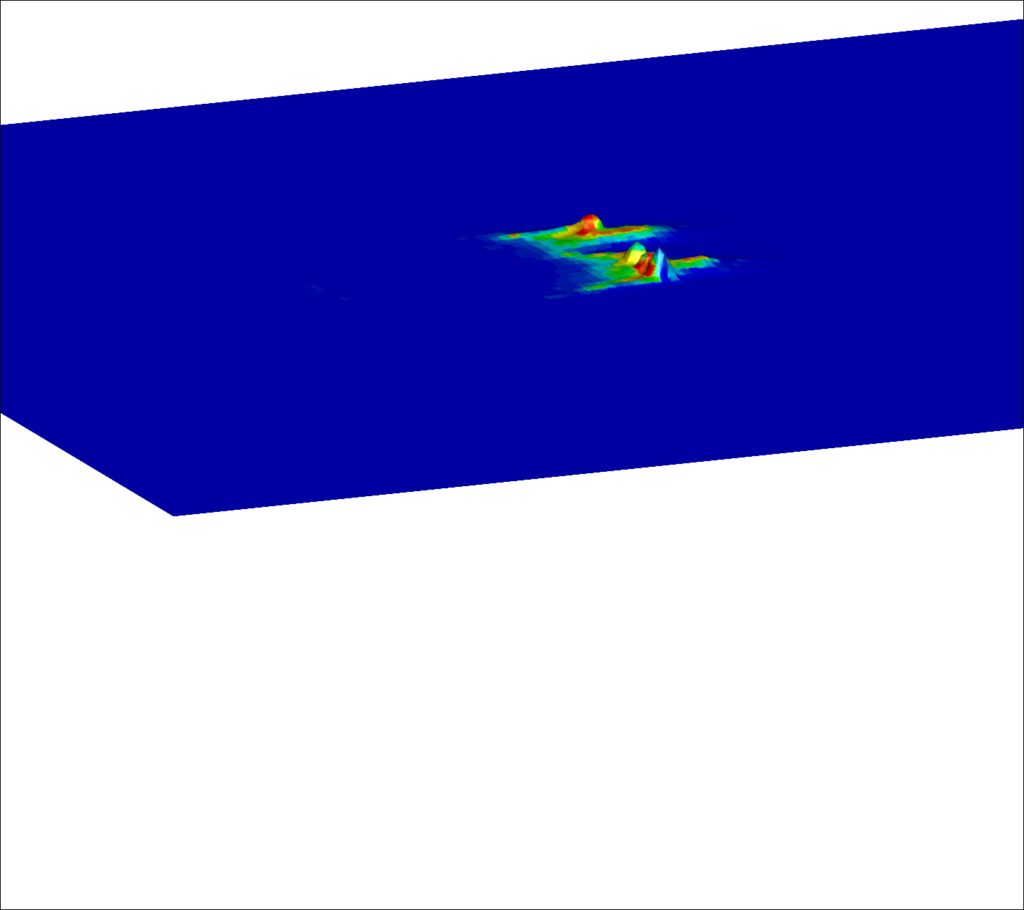

Mitigate Urea Deposits

Urea deposits are proven to be detrimental to urea/SCR systems, increasing engine back pressure and decreasing conversion efficiency. CONVERGE can efficiently and effectively identify where deposits will form. A series of robust physical models are available in CONVERGE to predict spray atomization and evaporation, spray-wall interaction, film transport, wall heat transfer, urea decomposition, and deposit formation, among other phenomena. An effective urea deposit model must account for surface temperature, which is dependent on heat transfer from the exhaust gas, the urea-water solution, and the heat loss to the surroundings. CONVERGE’s conjugate heat transfer (CHT) model can predict the accurate wall temperatures required for splashing and film evaporation models to identify locations on the wall that could cause deposition. CONVERGE’s CHT model also offers super-cycling, which can quickly achieve a statistically steady metal temperature without scaling the metal heat capacity. The fixed flow approach can substantially accelerate the film development and deposit formation modeling processes.

CONVERGE’s urea detailed decomposition model directly solves for the mass fraction of multiple urea deposit byproducts in a film. The deposit solidification model can be used in conjunction with the urea detailed decomposition model to isolate solid deposits from a liquid film. The solid deposits can adhere to the wall to simulate buildup behavior while the liquid moves freely. As the solid deposit builds up, CONVERGE can automatically adjust the triangles on the wall to accommodate the buildup. This movement of the wall triangles is fully coupled with the local flow solution and the liquid film transport.

Particulate Filters

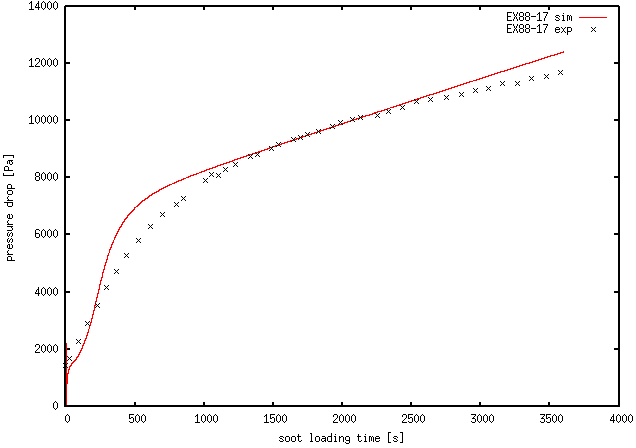

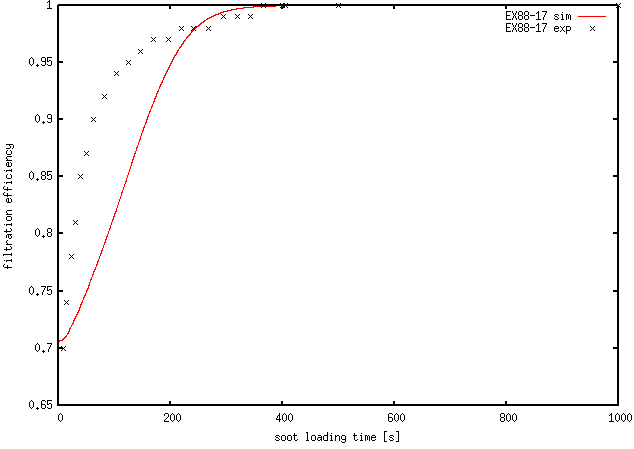

Particulate filters are a well-established method to trap soot produced by the engine. To meet increasingly stringent emissions regulations, engineers need to continuously improve filtration efficiency and minimize pressure drop for both gasoline (GPFs) and diesel particulate filters (DPFs). Compared to a conventional 0D/1D approach, 3D CFD modeling of DPFs and GPFs can offer more information regarding flow and pressure distribution as well as soot and ash accumulation profiles within the wall substrate and on the substrate surface. The filtration model implemented in CONVERGE is a simplified numerical model used widely in CFD to predict filtration efficiency. This model enables the user to modify the filter design at the microstructure level to improve soot storage and filtration efficiency. The filtration model can also be used to study the effects of various soot, ash, and catalytic washcoating profiles on the filter’s performance.

Whether you need quick turnaround on uniformity data or accurate urea deposit predictions, CONVERGE provides fast CFD and accurate models to support your aftertreatment design.

Istanbul Technical University; Ford Otosan Company

Canyurt, T.G., Ergin, S., Zeren, H.B., and Savcı, İ.H., “Experimental and Numerical Investigation on the Urea-Deposit Formation at Different Severities in Selective Catalytic Reduction Systems,” Applied Thermal Engineering, 214, 2022. DOI: https://doi.org/10.1016/j.applthermaleng.2022.118884

Convergent Science

Yang, P. and Drennan, S., “Predictions of Urea Deposit Formation With CFD Using Autonomous Meshing and Detailed Urea Decomposition,” SAE Paper 2021-01-0590, 2021. DOI: 10.4271/2021-01-0590

Convergent Science

Maciejewski, D., Sukheswalla, P., Wang, C., Drennan, S.A., and Chai, X., “Accelerating Accurate Urea/SCR Film Temperature Simulations to Time-Scales Needed for Urea Deposit Predictions,” SAE Paper 2019-01-0982, 2019. DOI: 10.4271/2019-01-0982

Politecnico di Torino; POWERTECH Engineering; Università degli Studi di Perugia; Cornaglia S.p.A.; STSE S.r.l.

Sapio, F., Millo, F., Fino, D., Monteverde, A., Sartoretti, E., Bianco, A., Postrioti, L., Tarabocchia, A., Buitoni, G., and Brizi, G., “Experimental and Numerical Analysis of Latest Generation Diesel Aftertreatment Systems,” SAE Paper 2019-24-0142, 2019. DOI: 10.4271/2019-24-0142

Hyundai Motor Company

Lee, K.S., “CONVERGE GT-SUITE Coupling Analysis for Denox System on SCR Catalyst,” IDAJ CAE Solution Conference, Seoul, Korea, Nov 21, 2016.

Isuzu Technical Center of America, Inc.

Sun, Y., Daya, R., and Verhnam, B., “Urea Deposit Prediction in the After-Treatment System,” CONVERGE User Conference, Madison, WI, United States, Sept 27-28, 2016.

Weichai Power Emissions Solutions Company

Zheng, G., “CFD Modeling of Urea Spray and Deposits for SCR Systems,” SAE Paper 2016-01-8077, 2016. DOI:10.4271/2016-01-8077

For more CONVERGE papers, please check out the bibliography (PDF).