Internal Combustion Engines

OVERCOMING THE HURDLES OF IC ENGINE DESIGN

Designing clean and efficient internal combustion (IC) engines is a critical component of the global effort to decarbonize transportation. To that end, the inclusion of alternative fuels, such as hydrogen, methanol, ethanol, and ammonia, is gaining prominence within the automotive industry. However, creating the next generation of IC engines comes with a host of challenges, due to their moving geometries, spatially and temporally varying conditions, complex combustion chemistry, and more. CONVERGE’s fully autonomous meshing and robust physical models make it a powerful tool for developing novel engine designs and advanced combustion strategies, such as pre-chamber and low-temperature combustion.

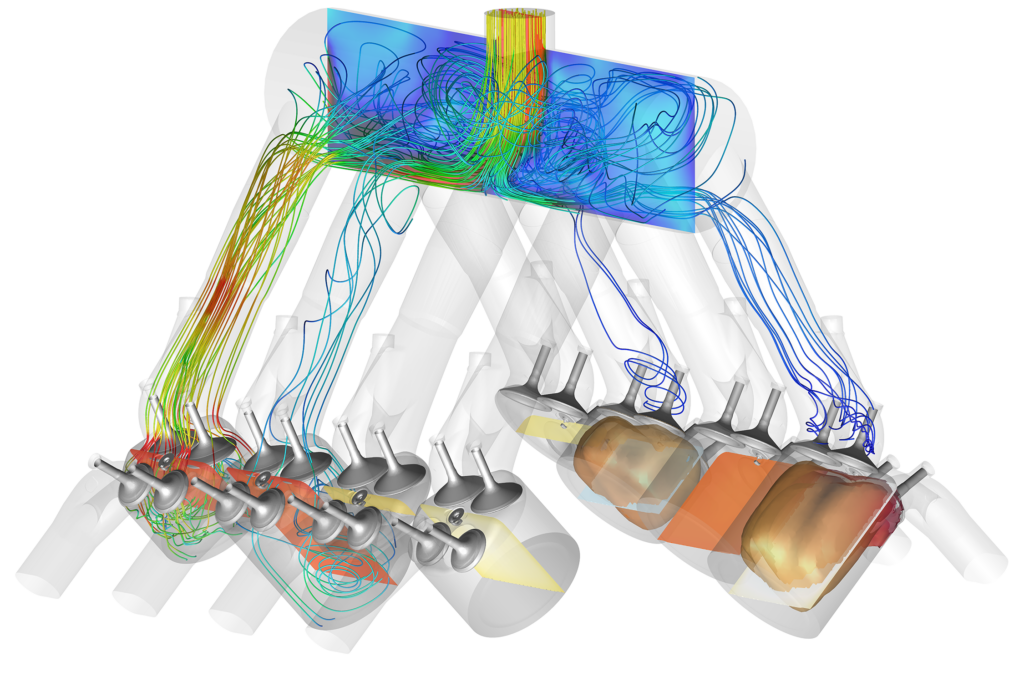

SPEND YOUR TIME ENGINEERING, NOT MESHING

In IC engines, creating sufficient mesh resolution to predict important spray and combustion phenomena is essential for accurate simulations. CONVERGE’s autonomous meshing with Adaptive Mesh Refinement (AMR) is a game changer in the field, as it produces a mesh at runtime and refines it throughout the simulation to easily account for moving geometries and eliminate user meshing time. AMR helps resolve 3D engine flow phenomena and propagating flames with reduced computational expense. Additionally, CONVERGE’s numerical techniques are immensely useful for capturing the necessary physics, including the shockwaves when hydrogen is injected directly into the combustion chamber at supersonic speeds.

COMBUSTION CHEMISTRY

CONVERGE’s SAGE detailed chemistry solver uses local conditions to calculate reaction rates based on the principles of chemical kinetics. This solver is fully coupled to the flow solver, but the chemistry and flow solvers parallelize independently of one another, which speeds up the simulation. The SAGE solver is a highly accurate and predictive way to model combustion and can accurately predict ignition as well as turbulent flame propagation. SAGE has the capability to handle a wide variety of fuels, including traditional fuels such as diesel and gasoline; alternative fuels like methanol, ethanol, ammonia, hydrogen, natural gas, biodiesel, and e-fuels; and dual- and multi-fuel scenarios. Users may take advantage of SAGE’s flexibility with any (properly formatted) chemical mechanism, but the Computational Chemistry Consortium mechanism (C3Mech), accessible through CONVERGE, adds convenience by providing ready access to well-validated chemistry for a multitude of fuel components.

Detailed chemistry modeling can be expensive; to mitigate this, CONVERGE incorporates several acceleration strategies such as adaptive zoning, dynamic mechanism reduction, and stiffness-based load balancing. These techniques, along with strategies designed to speed up species transport, allow users to select detailed reaction mechanisms to accurately simulate kinetically limited phenomena and engine emissions. As an example, the SAGE solver can be used with temperature-based AMR to model phenomena such as end-gas autoignition (i.e., engine knock).

In addition to the detailed chemistry solver, CONVERGE offers many other combustion modeling options for both premixed and non-premixed combustion so that you can choose the most suitable model for your simulation needs. These simplified models, including ECFM, ECFM3Z, G-Equation, and more, can provide high computational efficiency.

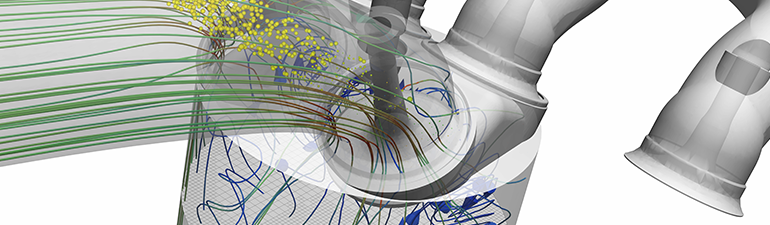

SPRAY AND TURBULENCE

Accurate injection, spray, and turbulence modeling is essential for predictive combustion simulations. CONVERGE includes both Reynolds-Averaged Navier-Stokes (RANS) and large eddy simulation (LES) turbulence models. For spray, CONVERGE offers a host of options to simulate injection, breakup, vaporization, boiling, cavitation, wall interaction, and other spray-related processes. With CONVERGE, users have access to liquid properties necessary for modeling liquid sprays, which facilitates the modeling of multi-component fuels. CONVERGE additionally has a fuel blender tool that can be used to generate multi-component fuel surrogates that mimic real fuel properties, reducing runtime while maintaining a high degree of accuracy.

EMISSIONS REDUCTION

Emissions regulations are becoming more stringent, presenting a notable challenge to engine manufacturers. To help them meet those regulations, CONVERGE can predict engine-out emissions, including soot and NOx, via its detailed chemistry solver or alternative models. For NOx modeling, CONVERGE includes the popular Zel’dovich model that predicts thermal NOx. For soot modeling, CONVERGE includes the Hiroyasu empirical model, detailed soot models like the Particulate Mimic (PM) and Particulate Size Mimic (PSM) models, as well as advanced phenomenological models based on detailed chemistry of PAH species. C3Mech provides users with access to accurate chemical kinetics for modeling NOx and PAHs. In order to ensure engine emissions comply with environmental standards, aftertreatment systems are designed to reduce NOx, CO, and soot with maximum efficiency and minimal maintenance costs. CONVERGE’s autonomous meshing, conjugate heat transfer modeling with super-cycling, and the fixed flow method can tackle some of the major challenges of designing effective and streamlined aftertreatment systems.

CONVERGE can solve the surface chemistry for several different aftertreatment systems, including diesel oxidation catalyst (DOC), selective catalyst reduction (SCR), lean NOx trap (LNT), and others. In addition, CONVERGE’s fixed flow method and time averaging capabilities can predict the production and transport of different molecular species, such as NH3 and HNCO, which enables uniformity simulations. Urea deposits can negatively affect aftertreatment systems by increasing engine back pressure and decreasing conversion efficiency. CONVERGE’s urea decomposition and deposit solidification models isolate solid deposits from a liquid film to accurately simulate buildup behavior.

THE ART OF THERMAL MANAGEMENT

Conjugate Heat Transfer Modeling

In IC engines, thermal transfer between solids and the surrounding fluids mutually affect one another, and your CFD software must be able to accurately account for this phenomenon. CONVERGE’s state-of-the-art conjugate heat transfer (CHT) model simultaneously predicts the heat transfer in both the fluid and solid portions of the domain. One of the primary challenges of CHT simulations is the large difference in time scales associated with heat transfer in the fluid and solid components. CONVERGE offers super-cycling, an approach to overcome the time-scale disparity by freezing the fluid solver until the heat transfer in the solid component reaches steady state.

Multi-Phase Flows

Modeling multi-phase flows is challenging due to the large difference in density between different phases. CONVERGE’s volume of fluid (VOF) method helps to resolve a sharp interface. The benefits of this method can be exemplified in a simulation of an oil jet-cooled piston, where engine oil is continuously sprayed at the piston undercrown to prevent overheating and piston damage. In this case, the VOF model captures the interface between the gas and liquid, while heat transfer is modeled with the CHT method. AMR automatically adjusts the grid resolution to accurately predict the important physics as the simulation progresses.

Multi-Stream Simulation

For the highest degree of accuracy, IC engine thermal management simulations should include all three phases (the solid metal components, liquid cooling, and gaseous combustion). The traditional approach in CONVERGE was to run two separate simulations, each modeling the interaction between two phases (i.e., liquid and gas, gas and solid). These individual simulations were then combined using a built-in heat transfer mapping tool. With CONVERGE’s advanced multi-stream capabilities, you can now model all phases in a single simulation, offering a streamlined, user-friendly approach.

Engine Cold Start

Engine cold start occurs when a vehicle is started after a long period of rest and is characterized by low wall temperatures, low RPM, and often incomplete combustion. Ignition can only begin once the engine is sufficiently warm and the walls are properly lubricated with oil that is up to temperature and flows well. To predict when ignition will occur, CONVERGE can model cold start with either a transient or constant engine speed. Using a transient RPM profile is often more computationally expensive because of the requirement to simulate multiple cycles. However, this approach yields significantly more accurate results because it captures the transient behavior of the boundary conditions during startup. With a constant RPM approach, modeling cold start will require you to run multiple simulations with a few select RPM profiles to represent the engine slowly heating up. With either approach, CONVERGE’s AMR will automatically refine the mesh when and where you need it, capturing the relevant flow parameters as the conditions of the engine change over time. Additionally, chemical mechanisms extracted from C3Mech can help accurately predict ignition with different fuels.

FLUID-STRUCTURE INTERACTION

CONVERGE’s fluid-structure interaction (FSI) modeling can capture the motion of flow-driven engine components. In a two-stroke engine, the inflow to the combustion chamber is supplied via the crankcase. When the pressure in the crankcase is higher than the intake port, reed valves inside the stuffing box remain closed. However, when the pressure in the crankcase is lower, these valves open to allow air to flow in. In these engines, FSI can effectively model the operation of the reed valves based on the effects of variable pressure, while CONVERGE’s autonomous meshing easily handles the mesh generation around the moving reed valves.

Turbochargers are commonly used in IC engines, where they can help achieve high power output and enhanced fuel efficiency. Unlike traditional turbochargers where the vanes in the turbine housing are fixed, variable geometry turbochargers feature adjustable vanes that control the flow of exhaust gasses onto the turbine wheel. With its autonomous meshing and FSI capabilities, CONVERGE can easily accommodate these different types of turbocharger geometries without sacrificing accuracy. AMR can refine the mesh to capture gradients in flow velocity, adding cells where and when they’re needed to achieve accurate results while maintaining a reasonable computational cost.

COUPLING WITH THIRD-PARTY SOFTWARE

To provide expanded simulation capabilities, CONVERGE can be coupled with third-party software packages such as GT-SUITE and Abaqus.

CONVERGE and GT-SUITE can be used together for coupled 3D/1D CFD simulations to maximize the core competencies of both softwares. For instance, coupling the two enables 3D time-accurate modeling of complex combustion dynamics, while employing computationally efficient 1D modeling for tailpipe back pressure calculations. Additional coupling applications for CONVERGE and GT-SUITE include engine cylinders, exhaust aftertreatment, and fluid-structure interaction simulations.

CONVERGE can also couple with the Abaqus FEA solver through the SIMULIA Co-simulation Engine, which facilitates runtime data exchange. This co-simulation enables users to solve advanced fluid-structure interaction problems, such as battery swelling and heart valves . In the first case, CONVERGE provides information about the pressure buildup and gas venting processes, while Abaqus predicts the 3D deformation of the battery casing. For the heart valve simulation, CONVERGE sends the pressure distribution to the Abaqus FEA solver, which then calculates the displacement of the valves and sends it back to CONVERGE.

To further improve the fidelity of system-level simulations, we have developed the CONVERGE co-simulation user-defined function (UDF), a generic 1D coupling interface. This UDF is designed to work with any 1D system simulation tool.

OPTIMIZING ENGINE PERFORMANCE

Genetic algorithms (GA) and design of experiments (DoE) are valuable for optimizing and understanding your engine; the former is advantageous for global optimization while the latter can be used for model interrogation. CONVERGE provides a model optimization tool, called CONGO, which automates the process of running a GA or DoE within CONVERGE by creating run directories, setting up input files, and collecting results upon completion. A CONGO executable is separate from CONVERGE and allows for optimization of user-selected parameters, spray rate-shapes, geometries, and more. The CONGO module in CONVERGE Studio tracks and coordinates all your genetic algorithm input files and directories for a smooth configuration. Running a GA on a CONVERGE model identifies the ideal set of parameters for a user-defined objective. Additionally, CONGO may run a DoE to capture trends of interest and visualize the different ways a certain set of parameters may be changed to improve the simulation.

Applying machine learning (ML) to DoE results allows for rapid optimization while concurrently running the simulations. Different ML algorithms work better for different problems; accordingly, in CONVERGE, an ensemble approach is used to select the best algorithm for the case at hand.

As an example, CONGO offers a piston bowl shape optimization tool, where a piston bowl geometry is first parameterized with a method of forces and then optimized for minimal fuel consumption within emissions constraints. For further optimization, you can couple CONVERGE with third-party CAD or geometry deformation tools.

COMPUTING IN THE FAST LANE

CONVERGE Horizon is a cloud computing platform designed to enable you to run faster and more cost-effective simulations. A partnership with Oracle Cloud Infrastructure (OCI) gives CONVERGE Horizon users on-demand access to OCI’s state-of-the-art bare metal servers and virtual machines at a discounted price. For additional cost savings, users also have access to CONVERGE on demand, allowing you to pay only for the software you need for your simulation workload.

Combustion concepts such as low-temperature combustion may introduce substantial cyclic variability. Capturing these cycle-to-cycle variations (CCV) requires many simulations—a process that can take weeks or even months. With CONVERGE Horizon’s computational power, you can simulate many engine cycles in a single day, making it possible to characterize CCV in a time frame compatible with industry R&D timelines.

COLLABORATIONS IN CODE

Convergent Science contributes to scientific advances related to combustion chemistry and IC engines through a wide network of collaborations. These connections allow us to validate our current models and implement new ones. For example, we collaborated with IFPEN to integrate a new version of the ECFM3Z combustion model into CONVERGE. IFPEN is at the forefront of model development and has spent more than 20 years researching and validating ECFM3Z. In addition, our collaborations with U.S. national labs and universities around the globe cover everything from spray model development to high-performance computing and combustion chemistry. Our investment in C3 gives us access to several computational chemistry tools, as well as the newest reaction mechanisms. These collaborations, and many others, bring CONVERGE closer to becoming a fully predictive CFD solver, leading to more efficient and effective designs in the IC engine industry.