Chemistry Tools

Computational fluid dynamics (CFD) simulations can be applied to chemical industries to analyze, customize, and optimize the design of chemical processes, such as reactors, heat exchangers, and distillation columns. For these processes, CFD can be used to predict fluid flow, heat transfer, mass transfer, and chemical reactions, helping engineers better understand physical and chemical processes. The use of chemistry tools in CFD has resulted in advancements in the chemical engineering, process, and automotive industries by reducing the cost of product and process development, shortening the time to market, increasing design conversions and yields, and improving design reliability. These advancements can include models for flow splits, reactor vessels, gaseous emissions, dosing points, shock tubes, ignition delay, process optimization, and contaminated waste.

CONVERGE offers an assortment of chemistry tools that can be used either on their own or in conjunction with CFD simulations. These tools allow you to study reacting systems, manipulate reaction mechanisms, and generate tables needed for certain simulations.

Zero-Dimensional Chemistry Tools

CONVERGE offers a wide range of zero-dimensional (0D) chemistry tools for fast, idealized calculations that provide both accuracy and speed.

The autoignition tool enables you to calculate ignition delay times for different combinations of temperature, pressure, and equivalence ratio of the fuel mixture. CONVERGE can also generate a tabulated kinetics of ignition (TKI) table, which can be used in 3D CFD simulations with simplified combustion models.

A very detailed chemical mechanism could contain hundreds or thousands of species; however, it’s usually not practical to use that detailed mechanism directly in a 3D CFD simulation. Instead, engineers will run the simulation with significantly fewer species. The mechanism reduction tool in CONVERGE can be used to reduce a large mechanism to a reasonable size for use in CFD simulations.

Similarly, a single chemical mechanism could contain thousands of individual reactions. CONVERGE’s 0D sensitivity analysis tool calculates the sensitivity coefficients for each reaction in your simulation and then evaluates how each reaction affects the resulting concentration, temperature, and reactivity of the mechanism. This function significantly aids in identifying which reactions or species are dominant and whether or not they are vital to your mechanism.

Another built-in feature is the variable volume tool, which prescribes the variation of the system volume to mimic physical systems. In a perfectly mixed system such as a homogeneous charge compression ignition (HCCI) engine, CONVERGE can calculate the variation of volume using engine parameters based on crank slider mechanisms.

Cases like the HCCI engine make use of the 0D engine type model, which is a closed system; on the other hand, idealized cases where perfect mixing is achieved inside the control volume use the well-stirred reactor (WSR), an open system. This feature allows users to explore combustion and flammability limits in highly turbulent systems. CONVERGE also includes the plug flow reactor (PFR), which employs 0D calculations to estimate the ignition, reaction, and emissions in continuously flowing systems. A PFR is essentially a chain of multiple WSRs, in which each WSR has neither axial nor radial diffusion. The PFR tool can be used to simulate emissions and chemical reactions in cylindrical flows.

CONVERGE’s chemical equilibrium (CEQ) solver can predict species concentrations at equilibrium. You have the option to enforce either constant enthalpy and pressure or constant temperature and pressure, which will result in different equilibrium conditions.

One-Dimensional Chemistry Tools

CONVERGE’s one-dimensional (1D) chemistry tools can assess laminar flamespeed, an important validation target.

To model a freely propagating flame, CONVERGE anchors the flame at a fixed position, and its 1D solver calculates the flow rate, or laminar flamespeed. Available within CONVERGE is a steady-state solver that uses 1D code to solve for the burned fuel/oxidizer composition and temperature. With this solver, you can perform 1D sensitivity analysis to determine the flame’s sensitivity to the variable outputs of your mechanism, including temperature and flamespeed. This 1D tool can generate laminar flamespeed tables that are needed for certain models, such as ECFM, ECFM3Z, FGM, G-Equation, and TFM. Historically, CFD simulations have relied on correlational data, or curve fits; however, specifying a laminar flamespeed table can provide a higher degree of accuracy.

CONVERGE’s 1D tools include the laminar counterflow calculation feature, which can calculate the temperature, species distribution, and strain rate between two inlet streams directed at each other. The counterflow flame method can calculate the strain rate at which flame extinction happens after the flow at the inlet is increased. A fuel and an oxidizer stream will produce a diffusion flame, while two premixed streams will produce a premixed flame. Depending on the combination, counterflow calculations will vary.

Reduce, Merge, Tune, Blend

Comprehensive combustion models often incorporate thousands of chemical species and reactions. CONVERGE allows you to generate a computationally efficient mechanism by reducing the number of chemical species and reactions while maintaining solution accuracy. CONVERGE’s mechanism reduction tool uses a basic skeletal mechanism reduction where all species deemed unimportant are removed from the original detailed mechanism. To choose which species, and corresponding reactions, are “unimportant,” a directed relation graph (DRG) is automatically constructed. A DRG calculates a coefficient for each species; if this coefficient is not high enough, it means the removal of that species will not significantly affect the production of other species. That species is removed, and users are presented with a visual representation of the reduced mechanism. You can make your DRG more precise by adding error propagation (DRGEP) with or without sensitivity analysis (DRGEPSA).

CONVERGE’s mechanism merge tool allows you to merge two reaction mechanisms. Since most mechanisms are developed for specific fuels, this tool is a convenient way to obtain an appropriate mechanism for your dual-fuel application.

Often, you will need to optimize your mechanism for specific points of interest by adjusting the reaction rates of selected reactions to match ignition delay or laminar flamespeed targets. CONVERGE’s mechanism tuning tool gives you the ability to tune reaction mechanisms to meet performance targets. Mechanism tuning can be done using CONGO, an in-house genetic algorithm optimization tool, or NLOPT, a library for nonlinear local and global optimization. Both optimization methodologies adjust the pre-exponential factors in the Arrhenius equation, an important formula for the temperature dependence of reaction rates.

It is often difficult to replicate a real fuel with the limited species in your mechanism; however, CONVERGE’s surrogate blender tool can help mitigate this obstacle. The surrogate blender can calculate important values for a multi-component fuel, such as the derived cetane number, the octane number, and the distillation curve values. By finding the mole fractions of specific fuel components that optimize prescribed property targets, the tool can also create a multi-component surrogate fuel.

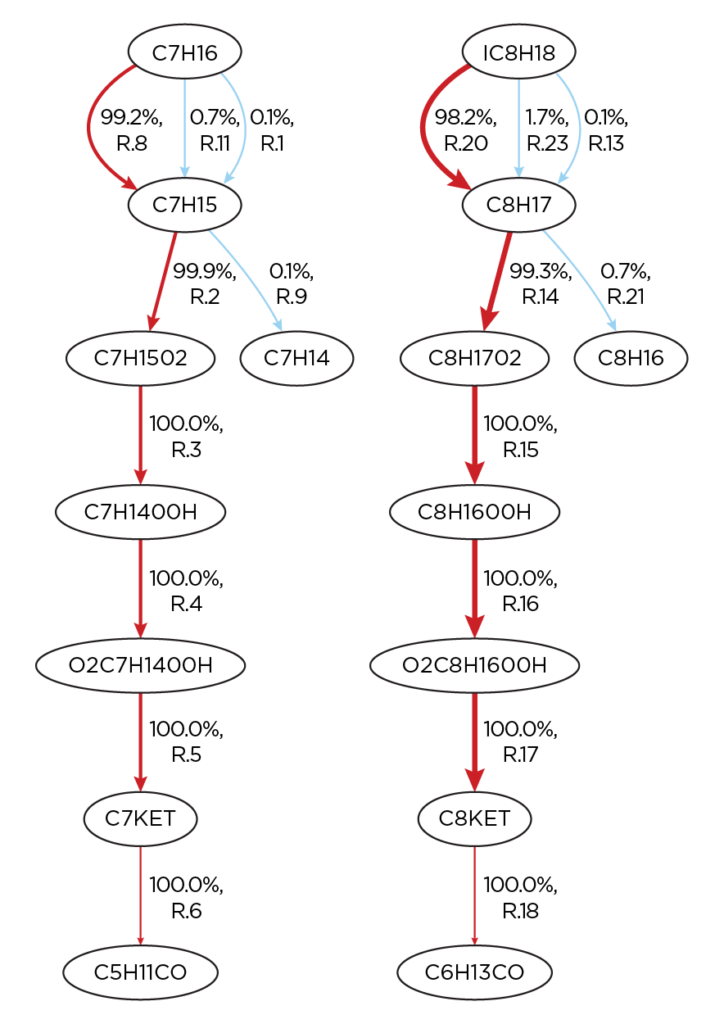

Chemical kinetic mechanisms tend to be exceptionally complex, so visualizing the reaction network can greatly enhance user understanding of the chemical processes that govern species formation and consumption. CONVERGE features the pathway flux analysis (PFA) tool, which generates diagrams that show the key species and reactions, so you can understand which species to keep during reduction. The PFA (Figure 1) differs from the DRG in its purpose as a pure visual aid, without the automatic reduction of the DRG tool.

Putting It All Together

For any CFD problem involving reacting flow, multiple steps may be necessary to conduct the simulation. CONVERGE’s chemistry tools allow you to conveniently and efficiently complete those steps. To simulate a reacting flow CFD problem, you must first decide how to model the fuel. CONVERGE’s blender tool supplies an efficient method of matching a real fuel. Next, you need to understand the chemistry of this surrogate fuel. The mechanism reduction, merge, and tune tools help you decide how to best modify the surrogate fuel to develop a meaningful mechanism. Finally, you need to model this mechanism based on a pre-existing algorithm. With CONVERGE, you can choose from options including the WSR or PFR reactors, 1D flamespeed, or 1D laminar counterflow calculations. And, of course, use it with CFD.

CONVERGE’s suite of chemistry tools is just one of the components that make CONVERGE a robust, multipurpose solver. CONVERGE’s chemistry capabilities mean our software has a broad scope of applications for not just CFD—but all of your chemical kinetics simulation needs. Interested in learning more about CONVERGE or CONVERGE’s chemistry tools? Contact us today!