Fluid-Structure Interaction

Capturing Real-Life Fluid-Structure Interaction

In the real world, solid objects influence the flow of surrounding fluids, and fluid flow can affect the motion of solid objects. These interactions between fluids and solids occur frequently in engineering applications, and capturing them accurately is crucial for obtaining realistic simulation results. CONVERGE features a variety of robust fluid-structure interaction (FSI) modeling capabilities, including rigid- and non-rigid-body FSI and contact modeling.

Rigid-Body FSI

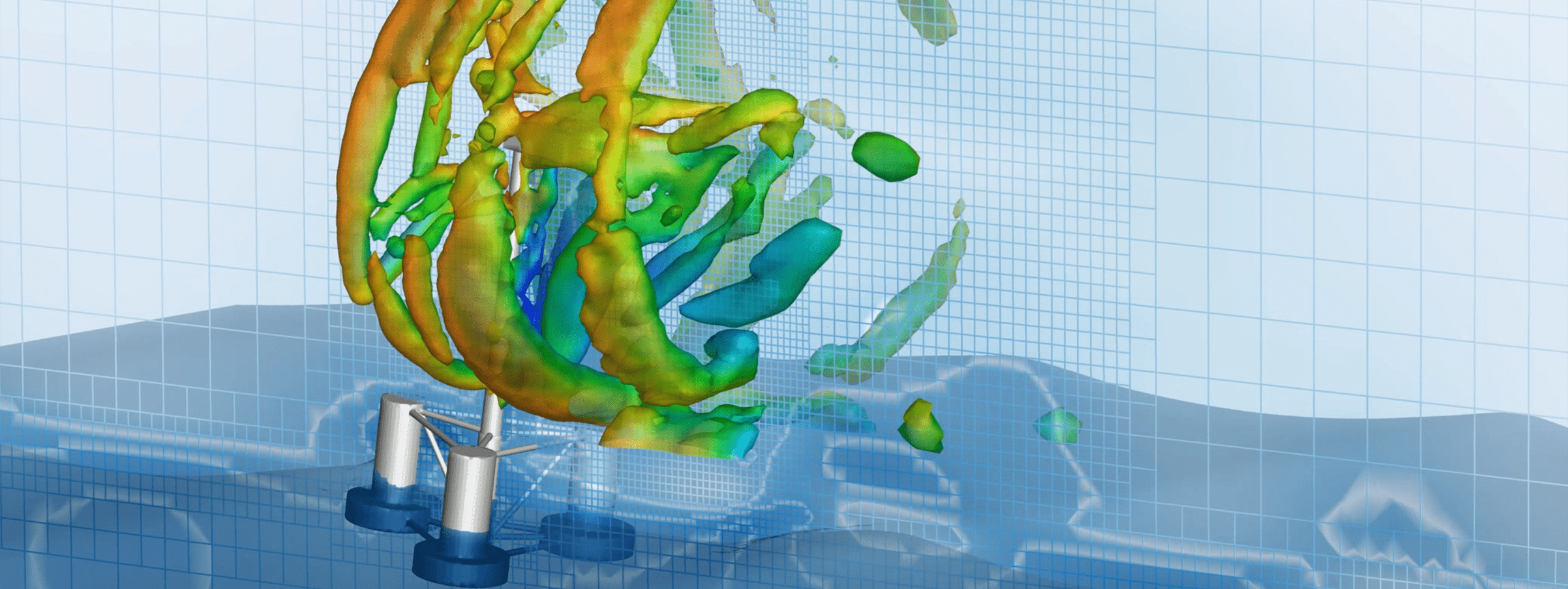

CONVERGE’s rigid-body FSI modeling can be used for solid objects that do not deform through shear, extension, or compression forces. With this model, the flow is solved at each simulation time-step, and the calculated pressure and viscous forces are used to advance the FSI object(s). In addition, CONVERGE features implicit FSI modeling, which increases the stability of the solver when simulating fluids and solids with similar densities. Implicit FSI opens the door to many applications, such as modeling floating wind turbines and subsea oil and gas applications.

In many CFD solvers, simulating FSI is challenging because the motion of the FSI object can be hard to predict a priori and, thus, it is hard to develop a meshing strategy. To avoid stretching or skewing the mesh, various techniques such as dynamic re-meshing or overset meshes are often employed, but these methods can be costly and introduce additional error into the solution. CONVERGE entirely eliminates these issues through its autonomous meshing capabilities. The mesh is automatically generated at every time step, adapting to the object’s motion and preserving the integrity of the mesh. In addition, CONVERGE’s Adaptive Mesh Refinement increases the computational efficiency of the simulation by intelligently adding cells in locations with important physical phenomena.

Beam Deformation

In addition to rigid-body FSI, CONVERGE supports FSI modeling for some non-rigid-body structures. The FSI beam model, useful for applications such as reed valves, treats the object as a one-dimensional Euler-Bernoulli beam and solves a simplified finite element problem to find the deformation of the beam due to fluid forces.

Complex Deformation via External FEA Coupling

CONVERGE enables the simulation of complex solid deformation due to FSI through coupling with the Abaqus finite element analysis (FEA) software, offered by Dassault Systèmes. In this coupled approach, CONVERGE calculates the fluid forces and passes them on to Abaqus at each time-step. The Abaqus solver uses those forces to calculate the deformation of the solid via an FEA approach, then transfers the deformation data back to CONVERGE. Coupling with Abaqus allows you to study complex problems including intake or exhaust valves deforming under fluid flow, reed valves deforming due to torsion forces, or membrane deformation for biomedical applications.

Contact Modeling

CONVERGE’s contact model can be used to simulate a moving solid object coming into contact with either a stationary solid structure or another solid object in motion. This model, which determines the new velocities of the FSI object when it impacts the boundaries or objects around it, can be used to simulate applications such as jittering valves in pumps, compressors, or flow control devices.

Multi-Physics Simulations

CONVERGE’s FSI modeling can be used in conjunction with other physical models to simulate complex multi-physics problems. For example, combining FSI with conjugate heat transfer modeling allows you to obtain a transient or steady state temperature distribution in FSI objects. With FSI and volume of fluid modeling, you can simulate many offshore and marine applications as well as cavitation in pump valves and liquid film interaction with compressor valves.