Oil & Gas

Solve Complex Flow Problems

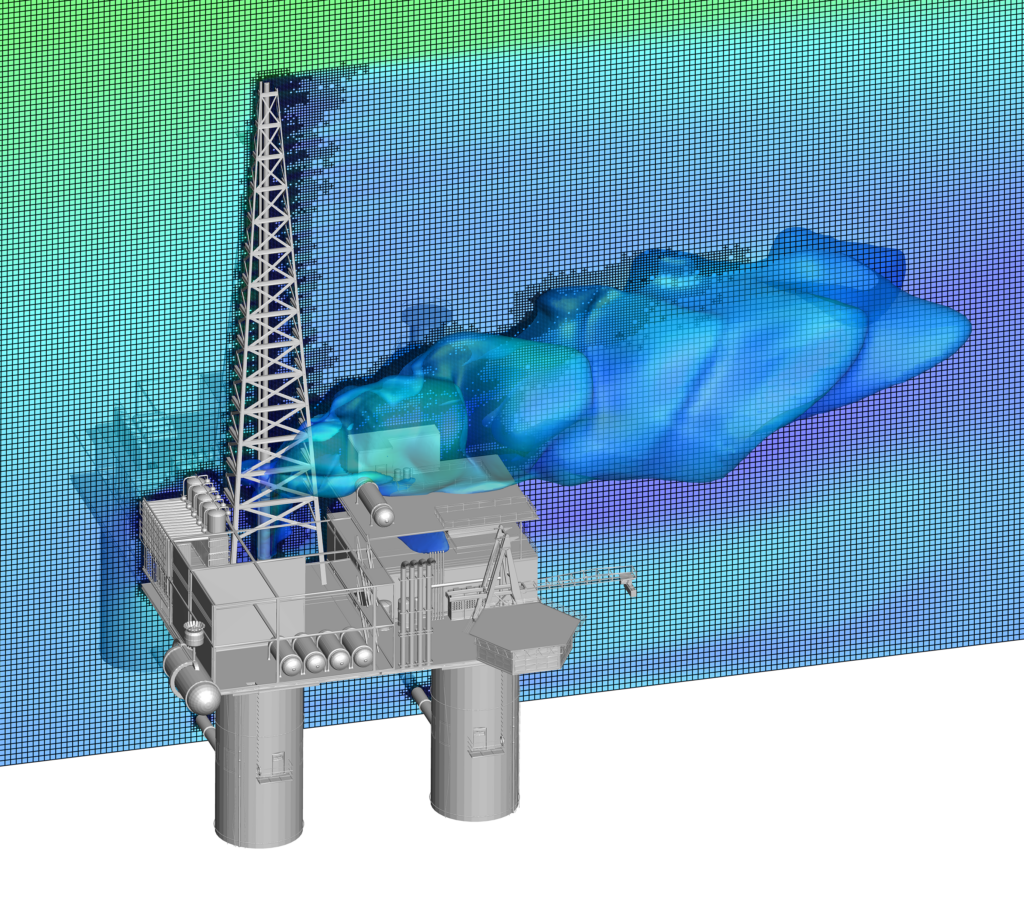

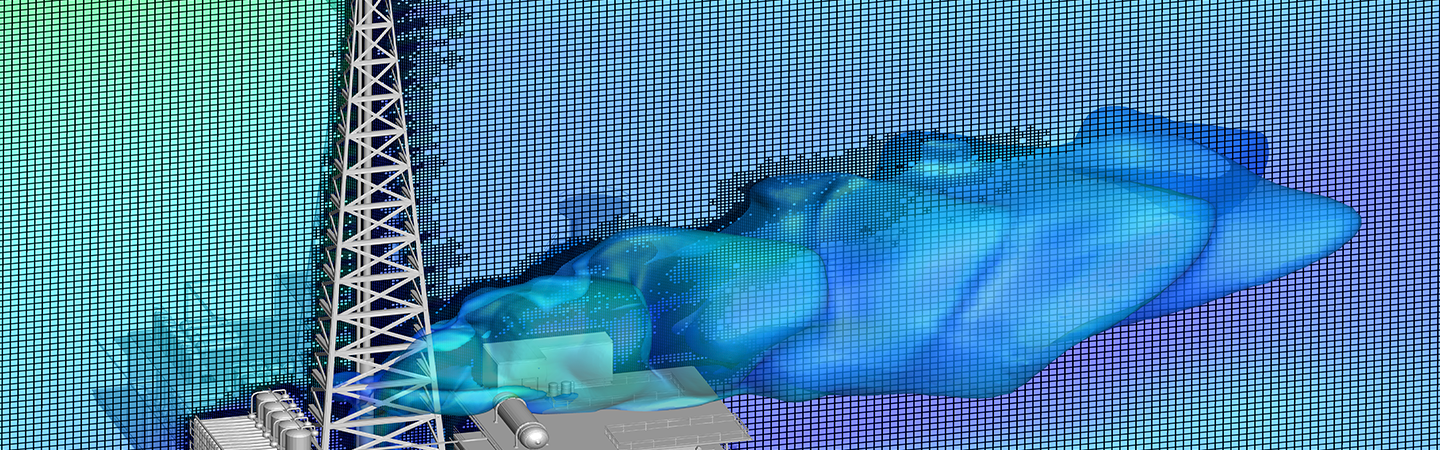

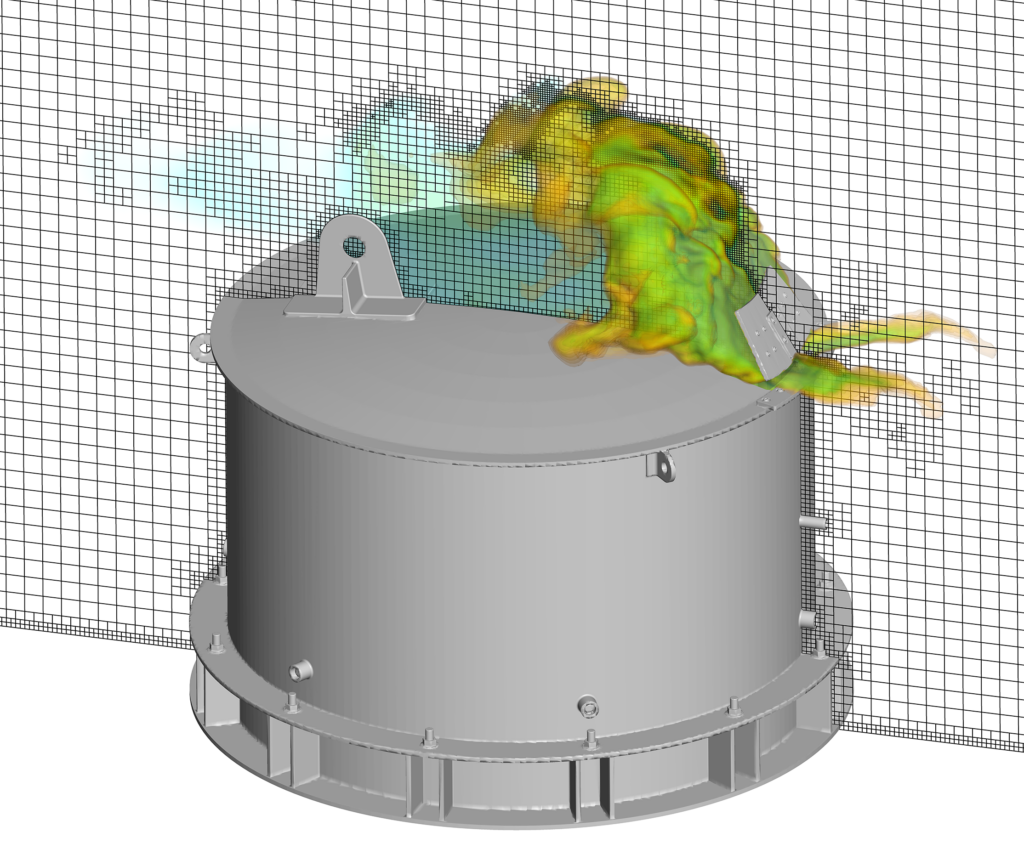

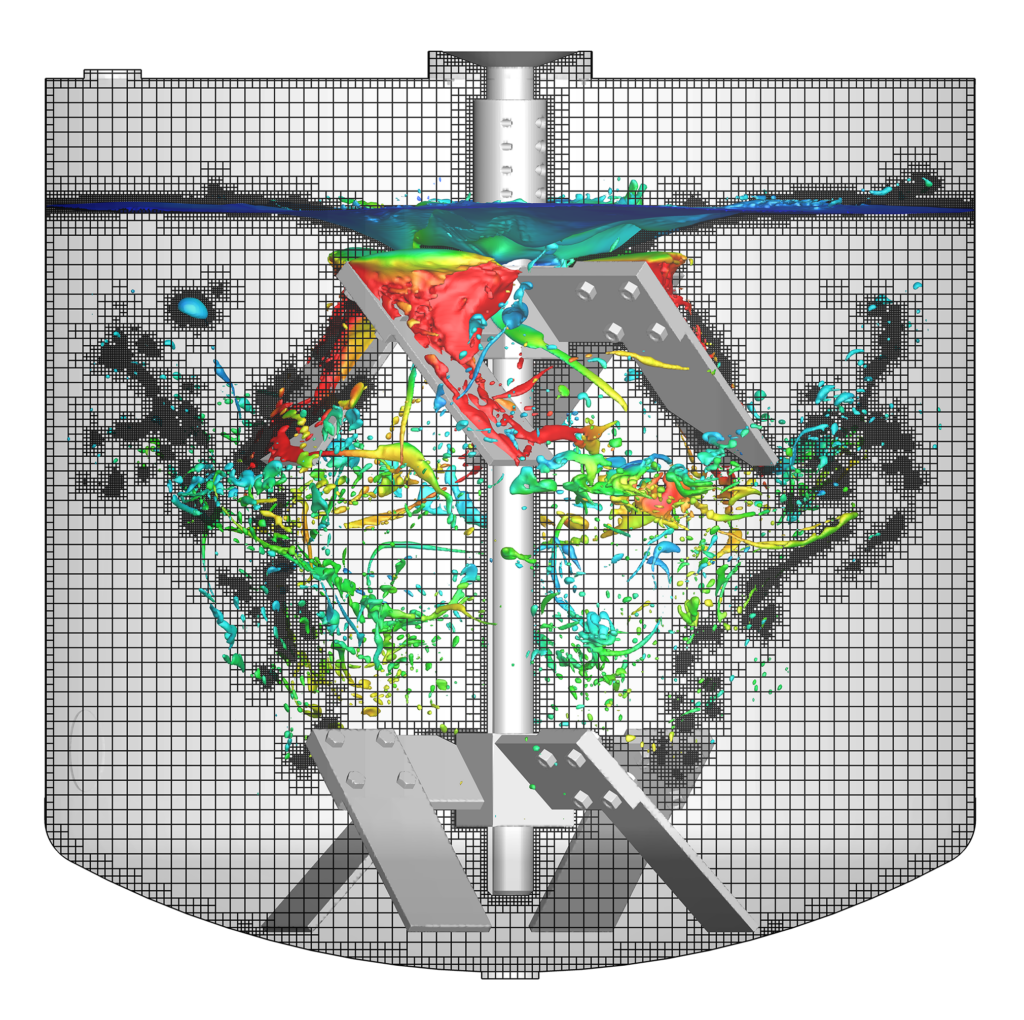

Understanding fluid flows is of critical importance in the oil and gas industry for extracting, refining, and delivering hydrocarbons and for designing equipment. CONVERGE CFD software offers a powerful option for simulating complex fluid flows and physical phenomena, whether you are modeling mixing tanks, gas leaks, heat transfer in drill bits, or wind and wave loads on offshore platforms.

Never Make a Mesh Again

No matter the industry, no one likes meshing. With fully autonomous meshing capabilities, CONVERGE eliminates all user meshing time. CONVERGE automatically generates an optimized mesh at runtime based on simple user-defined parameters. Throughout the simulation, CONVERGE invokes Adaptive Mesh Refinement (AMR) to dynamically refine the mesh to maximize both accuracy and efficiency.

Accurately Model Complex Moving Geometries

Moving meshes can cause artificial viscosity and reduce the accuracy of your simulation results. CONVERGE removes these errors by using a stationary mesh that is regenerated at each time-step to accommodate moving geometries. Additionally, CONVERGE employs a unique Cartesian cut-cell technique to perfectly represent your underlying geometry, no matter how complex.

Simplify Your CFD Workflow

Setting up your simulations is easy with CONVERGE’s graphical user interface, CONVERGE Studio. You can invoke powerful tools to prepare your geometry and select solver parameters. Then, you can leverage CONVERGE’s state-of-the-art physical models—including chemistry, combustion, spray, turbulence, and radiation—for a wide variety of applications. Finally, you can analyze your simulation results with CONVERGE Studio’s suite of post-processing and visualization tools, for a smooth workflow from start to finish.

Fluid-Structure Interaction

Since pressure and shear stress can cause deformation of a solid, and the motion of a solid object can change the flow of adjacent fluid, it is critical to capture fluid-structure interaction (FSI) in your CFD simulations. CONVERGE allows you to easily model rigid-body FSI and additionally supports some non-rigid-body structures. Furthermore, CONVERGE has a contact model that detects and properly simulates the interactions with walls and between objects.

Conjugate Heat Transfer

Solving conjugate heat transfer (CHT) between the fluid and solid portions of your domain can increase the accuracy of your simulation. However, CHT calculations can be computationally expensive due to the large difference in time scales associated with the heat transfer in the fluid versus the solid. CONVERGE uses a novel super-cycling approach to significantly reduce the computational cost of a CHT simulation.

Multi-Phase Flows

CONVERGE offers the Eulerian volume of fluid (VOF) method for modeling multi-phase flows. The VOF method locates and tracks the free surface in a liquid-gas flow or the interface in a liquid-liquid flow, and offers several methods for interface reconstruction. You can couple the VOF method with AMR to automatically increase grid resolution at the fluid-fluid interface, reducing numerical diffusion and resolving the interface at a reasonable computational cost.

Combustion

For modeling combustion, CONVERGE’s SAGE detailed chemistry solver is fully coupled with the flow solver for maximum accuracy and efficiency. CONVERGE also contains a variety of models for simulating non-premixed, partially premixed, and premixed flames. AMR allows you to resolve the flame front by adding cells when and where you need them.

Optimization

CONVERGE includes a model optimization tool that uses a genetic algorithm to efficiently and effectively find the best possible design for your flow-exposed components. And since CONVERGE creates the mesh for you, the time to conduct an optimization study is significantly reduced. Testing your designs numerically before building experimental prototypes saves you valuable time and money and results in an improved final product.

High-Performance Computing

The CFD industry is moving toward a many-core architecture, and simulations are moving from a handful of cores to hundreds or thousands of cores. We actively collaborate with industry, academic, and government partners to ensure that CONVERGE stays on the leading edge of technology and scales efficiently on many cores. To make high-performance computing resources available to everyone, we’ve launched CONVERGE Horizon, a cloud computing service that allows you to run larger and more cost-effective simulations. By partnering with Oracle Cloud Infrastructure (OCI), CONVERGE Horizon gives users on-demand access to OCI’s state-of-the-art bare metal servers and virtual machines at a discounted price. For further cost savings, CONVERGE Horizon users have access to CONVERGE on demand, allowing you to pay only for the software you need for your simulation workload. In the oil & gas industry, larger cases such as oil separators and capping stacks can benefit from being run on many cores. Since these cases have higher cell counts, they can be run more efficiently on CONVERGE Horizon. That being said, “smaller” cases in the oil & gas industry can still benefit from CONVERGE Horizon’s on-demand functionality.