Emobility

Simulate Key Phenomena in Electrical Systems

Designing efficient, durable, and safe electrical systems is critical as the number of electrified vehicles on the road increases rapidly. CONVERGE CFD software is ideally suited to simulations of 3D coupled flow, heat transfer, and chemistry in complex geometries with stationary or moving components. In addition, CONVERGE’s autonomous meshing eliminates user meshing time and reduces total time-to-solution. Taking advantage of these capabilities, you can efficiently and accurately investigate important physical processes in electromobility (emobility) systems, including electric motor cooling, battery cooling, and battery thermal runaway.

Battery Modeling

Heat Generation & Cooling

CONVERGE offers several options for modeling battery heat sources. With the equivalent circuit model, you can represent your battery as an electrical network and calculate the heat generation based on the current. This model can be used for either charging or discharging batteries. The electric potential solver, useful for batteries and other direct current applications, predicts the current and associated heat transfer based on the electric potential and electrical conductivity of the solid.

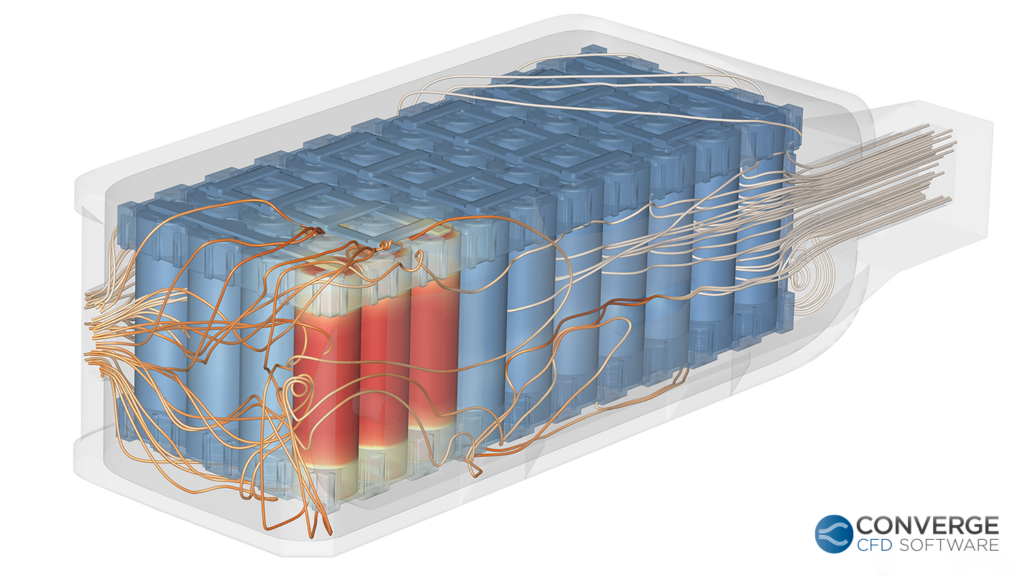

Since battery efficiency and longevity are significantly impacted by temperature, effective thermal management of the battery pack is crucial. CONVERGE offers robust conjugate heat transfer (CHT) modeling, as well as several CHT acceleration techniques, to assess both air and liquid cooling methods.

Thermal Runaway

Battery thermal runaway occurs when mechanical, thermal, or operational stress triggers a cascade of exothermic reactions in an electrochemical cell, causing the temperature to rapidly increase. As the temperature of the cell rises, it can lose stability and rupture, releasing its stored thermal/electrochemical energy. CONVERGE’s SAGE detailed chemistry solver enables you to model the chain of reactions that occur during thermal runaway. There are two thermal runaway mechanisms included in CONVERGE: Hatchard-Kim and Ren. In addition, you can easily implement any thermal runaway mechanism you want via user defined function.

A battery cell in thermal runaway generates a substantial amount of heat, which can cause nearby cells to also enter thermal runaway. CONVERGE’s Adaptive Mesh Refinement (AMR) refines the mesh throughout the simulation based on the curvature of field variables or the value of the field variables themselves, allowing you to efficiently capture important physical phenomena. By applying temperature-based AMR to the solid components of the battery, CONVERGE is able to predict the propagation of thermal runaway to adjacent cells.

Cell Venting & Ignition Risk

Thermal runaway can cause cells to vent gases into the battery pack, either by design or malfunction. With CONVERGE, you can track the propagation of vent gas species and assess the change in solid temperatures in the area where the venting occurs. Once gas has been vented, there is a possibility it could ignite, causing an explosion or battery fire. CONVERGE enables you to assess battery safety by investigating the risk of ignition and subsequent combustion of vent gases.

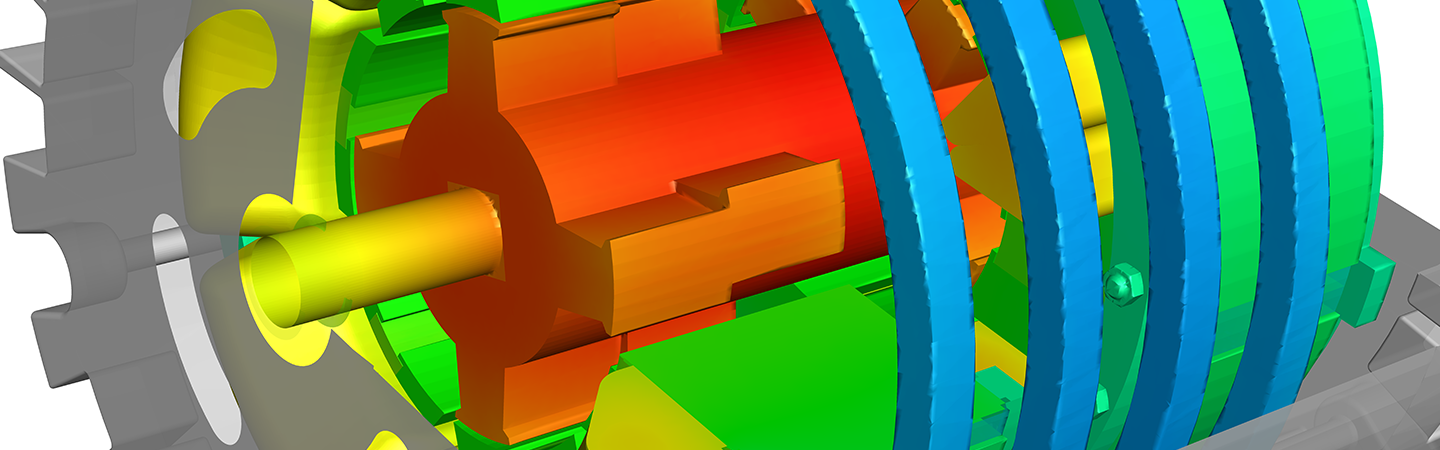

Electric Motor Cooling

Electric motor manufacturers are increasing the power density of their designs, necessitating more efficient methods to remove the heat generated by the motor. Excessively high temperatures can cause demagnetization of the permanent magnets and the breakdown of the winding insulation, both of which are catastrophic for the device. Motor power and the associated efficiency are thus strongly tied to the effectiveness of the cooling strategy.

The first step to analyzing cooling strategies is to calculate the heat generated by the motor. CONVERGE can read in electromagnetic heat source output from JSOL Corporation’s JMAG-Designer software, which allows you to obtain a highly accurate temperature distribution. CONVERGE Studio reads in the geometry from the JMAG NASTRAN file and automatically assigns thermal boundary conditions or a volumetric heat generation source for a CHT simulation.

With CONVERGE’s CHT modeling capabilities, you can efficiently analyze a variety of motor cooling methods, including air cooling, water jacket cooling, and oil cooling. For oil-cooled motors, CONVERGE’s volume of fluid (VOF) modeling, complete with several high-fidelity interface capturing schemes, allows you to obtain an accurate representation of oil coverage.

Fully Autonomous Meshing

CONVERGE’s autonomous meshing is designed to simplify your workflow and reduce time-to-solution. At runtime, CONVERGE automatically generates a Cartesian mesh based on a few simple user-defined parameters, effectively eliminating all user meshing time. CONVERGE employs a novel cut-cell technique that ensures a perfect representation of your geometry, no matter how complex. For moving geometries, CONVERGE regenerates the mesh at each time-step to accommodate the motion without deforming the mesh, resulting in a more accurate solution. Additionally, Adaptive Mesh Refinement intelligently adds and removes cells throughout the simulation to resolve complex phenomena such as the flame front in a battery pack ignition simulation or large temperature gradients in your cooling analysis as efficiently as possible.

Certain simulations may benefit from adding a local non-Cartesian mesh, for example, to resolve a thermal boundary layer around the electrochemical cells in your battery pack or to resolve small rotor-stator gaps in an electric motor. CONVERGE allows you to create an inlaid mesh in a portion of your simulation domain, which can potentially offer increased accuracy with a shorter runtime.

Accelerate Your CHT Simulations

Predicting conjugate heat transfer is critical for obtaining accurate results in many emobility applications, including battery and motor cooling and thermal runaway. However, CHT calculations can be computationally expensive due to the disparate time scales of heat transfer in fluids and solids. With CONVERGE, you can use the super-cycling method to overcome this time scale disparity. When using super-cycling, the fluid solver is periodically frozen while the heat transfer in the solid is allowed to progress either to steady-state or for a user-specified period of time. This method significantly reduces the time it takes to run a CHT simulation.

Another acceleration strategy is the fixed flow method, which you can employ for cases where the flow changes less rapidly than other physical phenomena in your computational domain. By freezing the flow field and solving the flow for only short periods of time, you can reduce the computational expense of the simulation. This is particularly useful for cases that require you to simulate a long period of time, for example, the heating of adjacent cells due to vent gas from a thermal runaway cell in a battery pack.

Fuel Cell Modeling

Polymer electrolyte membrane fuel cells (PEMFC), also known as proton exchange membrane fuel cells, generate power by converting chemical energy released from the electrochemical reaction between hydrogen and oxygen into electrical energy. PEMFC have a high power density with a relatively low weight, and they usually operate around temperatures of 140-185°F, making them attractive for applications in the automotive industry. However, their usage requires platinum, an expensive catalyst, and hydrogen, which presents challenges due to its low volumetric energy density.

CFD helps engineers improve the performance and efficiency of PEMFC by predicting the impact of fluid velocities and pressures, species concentrations, polarization curves, and the relationship between fuel cell voltage and current. With its autonomous meshing capabilities, CONVERGE can effectively capture the complexity of modern fuel cell geometries, avoiding the additional pre-processing burden associated with mesh generation in many other CFD solvers. Conjugate heat transfer models in CONVERGE can be used to calculate the heat transfer throughout the fuel cell stack to locate regions of low or high temperature. Additionally, CONVERGE’s multi-phase modeling can simulate the flow of liquids and gases in the reactant supply channels and gas diffusion layers, which are typically represented as porous media. This feature can help PEMFC manufacturers predict local water content and simulate liquid water transport, which are important for evaluating the performance of the fuel cell. The fully coupled solution of electrochemistry, multi-phase fluid dynamics, and heat transfer within CONVERGE allows engineers to study the activation and mass transport losses of PEMFC, which can degrade cell performance, and design ways to mitigate them.