Ease of Use

YOUR CFD WORKFLOW MADE SIMPLE

Setting up a CFD simulation can be a hassle in many codes—that’s why CONVERGE was designed with ease of use in mind. To that end, all CONVERGE licenses come with CONVERGE Studio, a straightforward graphical user interface that contains a multitude of tools to assist you with your CFD workflow. CONVERGE Studio takes you from case setup to post-processing, all in one program.

IMPORT AND PREP YOUR GEOMETRY

No matter the format of your geometry file, CONVERGE Studio can handle it. CONVERGE Studio is equipped with several Spatial products that can directly import CAD files, including CATIA and SolidWorks formats, and triangulate or quadrangulate the surface for CONVERGE. Spatial preserves topological identifiers when you import the geometry, saving you time in the boundary flagging process.

After importing your geometry, you can run the diagnostics tool to find any problems. CONVERGE Studio includes a number of tools for repairing problems in a geometry and for simple manipulations, such as rotating, scaling, or merging geometries. With an additional license for Polygonica, you can access the more advanced geometry manipulation tools packaged with CONVERGE Studio.

SET UP YOUR CASE

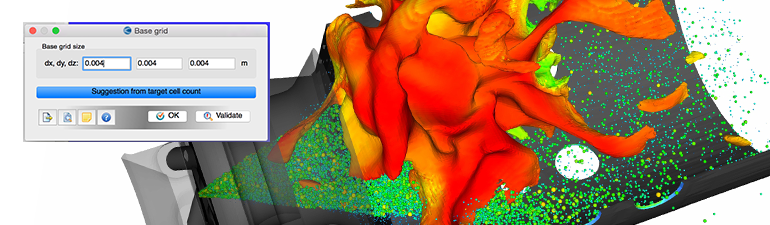

The Case Setup dock guides you through the simulation setup process, including assigning boundary and initial conditions, selecting grid control parameters and physical models, and configuring your output files. Through Grid Control, you can define the parameters for CONVERGE’s automated mesh generation and Adaptive Mesh Refinement, which automatically refines the mesh based on the specified flow variables. If you are modeling a wall-bounded flow or an external flow, you can avail yourself of CONVERGE’s inlaid meshing to create a near-wall boundary layer mesh or a flow-aligned mesh in a portion of the computational domain.

If there are routinized elements in your workflow, you can automate your tasks using CONVERGE Studio’s Script Editor. Write your own script, or let us write one for you, that can automatically update your geometry, change your case setup parameters, and make calculations, among many other possibilities.

CHECK YOUR WORK

CONVERGE Studio contains many tools to help you make sure your simulation will run smoothly. The Timing map allows you to view the timing of all events in the simulation (e.g., OPEN/CLOSE, embedding, sources and sinks, AMR) and see whether each event is cyclic, permanent, or sequential. For cases with moving boundaries, you can use the animation feature to ensure your geometry is moving as intended before running the simulation. If you want to check on how your mesh is looking, use our Grid Preview tool to view it in all three planes.

OPTIMIZE YOUR DESIGN

The CONGO module in CONVERGE Studio automates the process of running a genetic algorithm optimization or a design of experiments model interrogation. CONGO creates run directories and sets up input files for CONVERGE, automatically launches jobs and monitors run progress, and collects results upon completion. If you are looking to optimize your design, CONGO can speed up a costly process.

Design of experiments allows you to learn more about your model, conduct parameter sweeps, or perform large-scale characterizations of the search space for optimization or uncertainty quantification.

Genetic algorithms use a survival of the fittest approach to determine the optimal parameters for your design. If you want to optimize the layout of a wind farm or find the propeller design with maximum thrust, simply set up the initial optimization by defining which parameters to vary, a range for the parameters, and the input template directory of the CONVERGE case, and CONGO takes it from there.

ANALYZE YOUR RESULTS, VISUALIZE YOUR SIMULATION

The Line Plotting module allows you to monitor key variables during the simulation and visualize your results once the simulation is complete. CONVERGE Studio can read in any properly formatted data file, so you can import and plot experimental data or other results and compare them with your CONVERGE simulation.

CONVERGE offers the option to perform in situ post-processing, in which the data is automatically post-processed while the simulation is running. In CONVERGE Studio, you can select pre-recorded scripts for common operations, such as plotting data over a line or a slice. This saves you a significant amount of time and storage, especially if you are running a large case or cases with frequent data points. You can use ParaView Catalyst to make your post-processing completely autonomous, no matter how large or small your case is.

If you prefer traditional post-processing methods, you can use Studio ParaView or Tecplot for CONVERGE to visualize your results after your simulation is complete. Studio ParaView is tailored for CONVERGE users and integrated into CONVERGE Studio. Tecplot for CONVERGE is a specialized version of Tecplot 360 included free of charge with a CONVERGE license. These post-processors allow you to visualize cut-planes, isosurfaces, and streamtraces as well as create animations of your simulation. You can also use Studio ParaView to record more advanced scripts for use with ParaView Catalyst.

And you’re not limited to Studio ParaView or Tecplot for CONVERGE. To use your preferred post-processing software, simply convert your CONVERGE output files with our post_convert tool into formats readable by a wide range of post-processing programs, such as FieldView or EnSight.

UNSURE ABOUT CASE SETUP? REVIEW OUR EXAMPLE CASES

CONVERGE Studio comes preloaded with dozens of example cases that consist of a geometry and the accompanying input parameters. You can run these cases (and read the corresponding Example Case Notes) to familiarize yourself with CONVERGE and with the setup for a particular type of case.

The Example Case Notes provide an executive overview, with details on the most important parts of the case setup. If you have a similar case, you can simply edit one of the example cases rather than start a new case from scratch. CONVERGE Studio features example cases that are applicable to many industries, including IC engines, gas turbines, fuel injectors and sprays, exhaust aftertreatment, compressors, pumps, valves, electromobility, and others.