Author:

Allie Yuxin Lin

Marketing Writer

Imagine you’re a CFD engineer and you want to run a combustion simulation for a certain kind of reacting flow device. But before you can do that, you need to find a chemical mechanism that can mathematically represent the chemistry within the reacting fluid. So you scour the available literature to find published mechanisms from third parties that fit your case conditions. This time-consuming and inefficient process prompted us, and other like-minded individuals across academia and industry, to seek a more consolidated alternative.

The Computational Chemistry Consortium (C3), the brainchild of Convergent Science owners Kelly Senecal, Dan Lee, Eric Pomraning, and Keith Richards, was established with the goal of creating a comprehensive and detailed mechanism that would serve as an all-inclusive solution for fuel combustion chemistry. Creating this repository of mechanisms would also help us investigate and develop alternative fuels to create more sustainable technologies. Professor Henry Curran from the University of Galway leads the consortium from the technical side, working with research groups whose respective areas of expertise complement each other, including the University of Galway, Lawrence Livermore National Laboratory, Argonne National Laboratory, Politecnico di Milano, and RWTH Aachen University.

The summer of 2018 marked a milestone in combustion chemistry, as C3 officially kicked off. Following the directional guidance from a diverse group of industry partners, C3 develops chemical mechanisms that include pollutant chemistry like PAH and NOx, creates tools for generating surrogate and multi-fuel mechanisms, and improves reduction and merging tools. C3 operates with a top-down approach, featuring one large mechanism from which users can extract the specific chemistry for their fuel. This method allows C3’s technical team to validate the mechanism as a whole, rather than combine many small, independently-validated mechanisms. In December 2021, C3 published the first version of their mechanism, making it widely available to the combustion community. Since then, the mechanism has been integrated into our software, allowing you to combine the flexibility of C3 with the power of CONVERGE.

To generate your fuel chemistry mechanism with CONVERGE, start by identifying all the individual components for your fuel surrogate. CONVERGE offers a surrogate blender tool where you can specify fuel properties such as viscosity, H/C ratio, octane number, distillation data, and ignition delay. The blender tool will then use mixing rules to match the specified fuel properties and come up with a fuel surrogate. Alternatively, the experienced user may choose to handpick certain fuel species according to information laid out in a test fuel’s spec sheet.

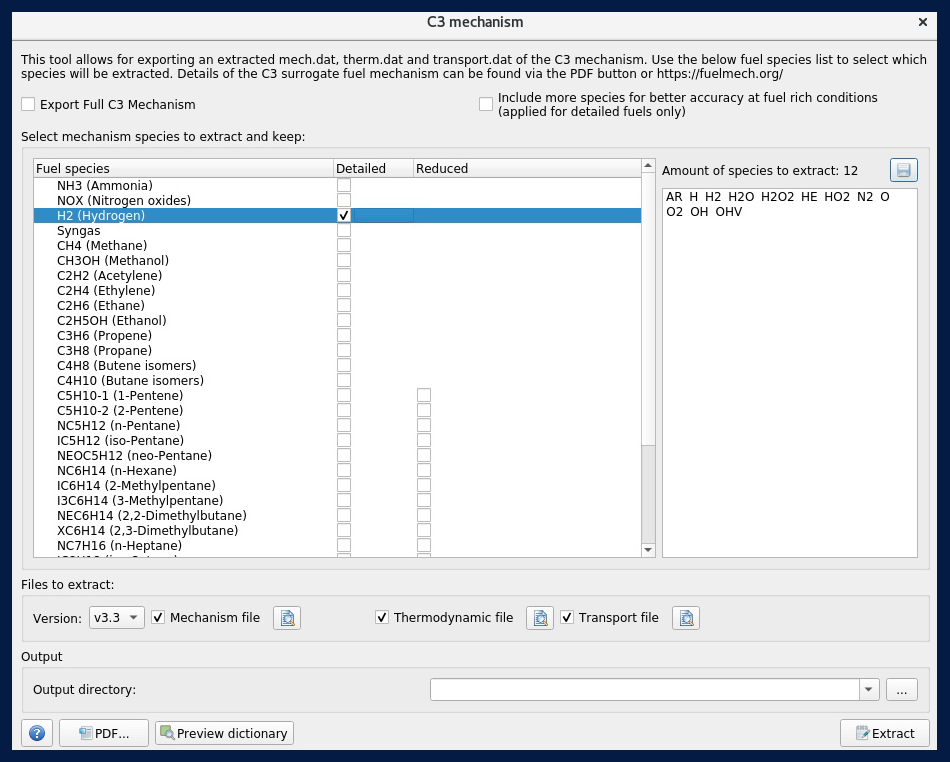

After you’ve identified your fuel surrogate, you can use the extraction tool in CONVERGE Studio, which was designed specifically for the purpose of extracting fuel chemistry from the parent C3 mechanism.

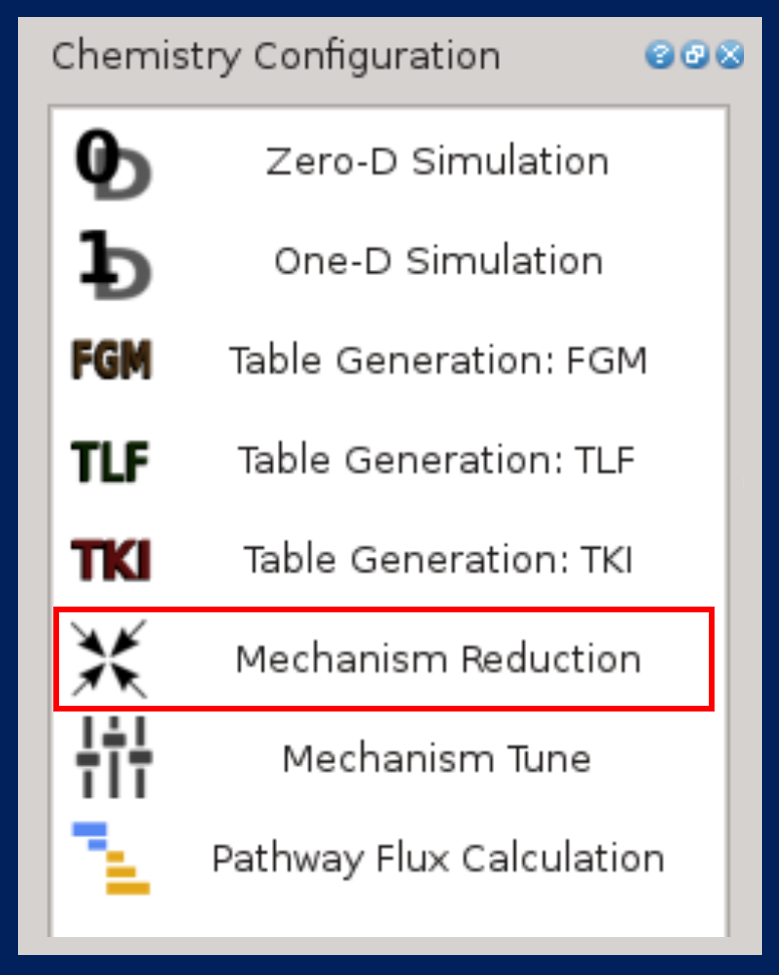

In most cases involving traditional hydrocarbon fuels, your extracted mechanism will have hundreds to thousands of species, which is far too many to use for a 3D CFD simulation. To ensure computational efficiency while maintaining solution accuracy, you should reduce your mechanism to a manageable size using CONVERGE’s mechanism reduction process.

A key component of this process in CONVERGE is the analysis of autoignition, extinction, speciation, and/or laminar flamespeed simulations. Therefore, before you can begin your reduction process, you must consider the specific conditions of your engine/combustor under which these simulations are evaluated. These operating conditions include pressure, unburnt temperature, equivalence ratio, and EGR fractions. For example, if your mechanism is meant to be used for a diesel engine simulation, you must select a pressure range from the start of injection to peak cylinder pressure.

To reduce the number of species, a directed relation graph (DRG) will be constructed and error propagation (DRGEP) can be added for further precision. The DRGEP methodology works to remove species and corresponding reactions within the user-specified error bounds of ignition delay, extinction, speciation, and/or laminar flamespeed. Once the number of species is ~500, sensitivity analysis (SA) can be added to the existing DRGEP methodology for further reduction of species. The optimal resulting mechanism will have calculations that fall within a user-specified range and a reduced number of species, making these mechanisms practical for 3D combustion simulations.

When you have obtained the optimal reduced mechanism, the reaction rates of the most sensitive reactions can be tuned to match specific targets of this mechanism to those of the parent mechanism. Similarly to the reduction process, these targets are speciation, extinction, laminar flamespeed, and/or ignition delay. You can tune your mechanism using CONVERGE’s mechanism tuning tools, such as NLOPT, an open-source library for nonlinear local and global optimization; the MONTE-CARLO method, which uses randomization to solve problems that may be deterministic in principle; or CONGO, CONVERGE’s in-house genetic algorithm optimization tool. These methods focus on the pre-exponential factor, A, or the activation energy in the Arrhenius reaction equation.

After completing these steps, your reduced chemical mechanism is ready to be run in 3D CFD simulations. The flexibility, versatility, and ingenuity of C3 simplifies the process of modeling both traditional and alternative fuels in a variety of applications where combustion is involved. With C3, your days of manually searching through the literature for a specific mechanism are over. Welcome to a new era of ease!

If you would like to help set the direction of future C3 efforts and have access to our mechanisms before they are publicly available, we invite you to join our consortium. To learn more, please contact C3 Director Dr. Kelly Senecal at [email protected].