Author:

Elizabeth Favreau

Marketing Writing Team Lead

Designing an efficient and effective compressor requires a detailed understanding of the device’s internal flow field. Experimental measurements provide useful information, but they have some disadvantages: building prototypes for testing is time-consuming and expensive, there is limited space inside the machine to insert probes, and the probes themselves can alter the flow field.

Daikin Industries, a leading manufacturer of advanced, high-quality air conditioning systems, uses CFD to help fill in those gaps. Simulation provides a more comprehensive picture of the internal workings of the compressor, outputting information that’s difficult to obtain experimentally.

Recently, Daikin integrated CONVERGE into their development process to help them analyze their swing compressor design. Because of its autonomous meshing, CONVERGE saves Daikin engineers more than two weeks per simulation compared to their previous CFD software, allowing them to more rapidly iterate on designs.

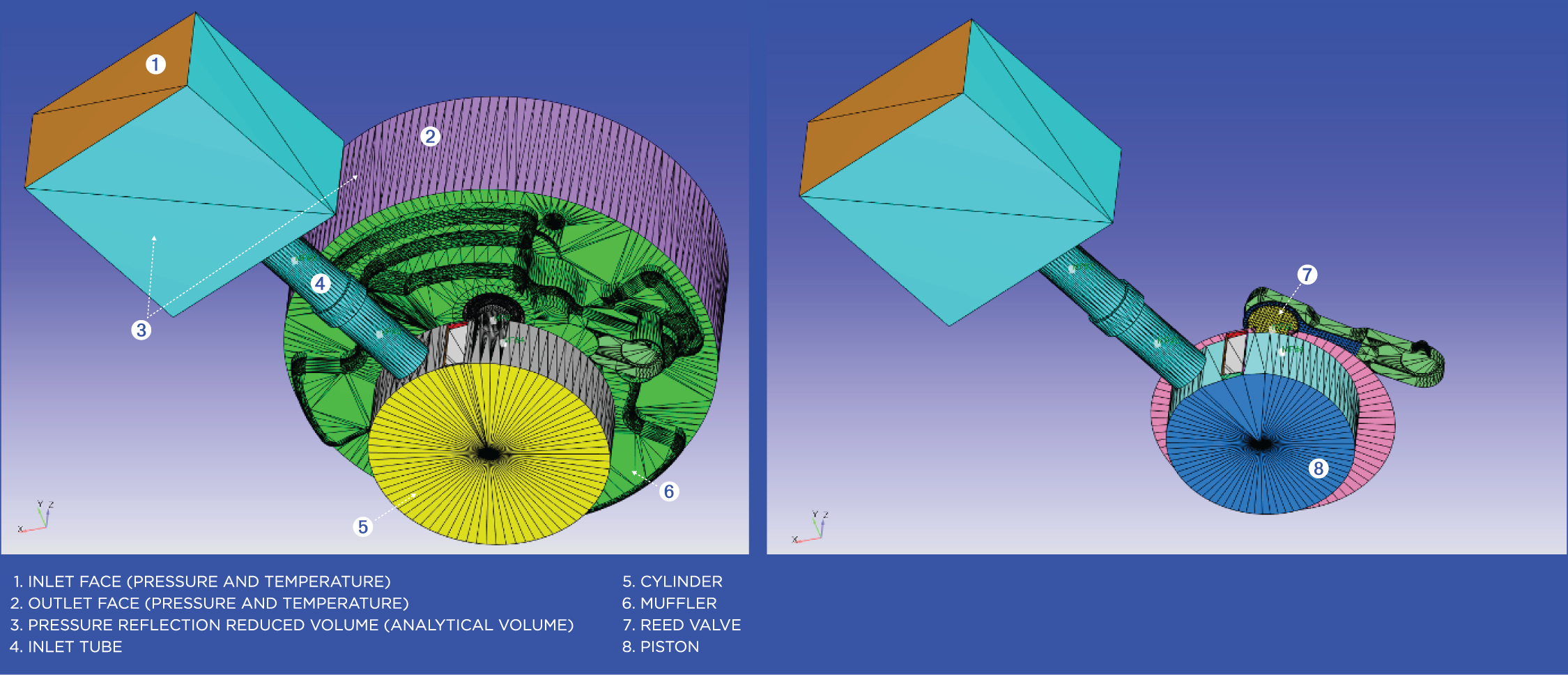

Daikin’s swing compressor is similar to a traditional rotary compressor, but it exhibits less leakage and can achieve higher efficiencies. The geometry of the swing compressor is shown in Figure 1.

Daikin takes advantage of CFD to identify and solve problems in their compressors during the design phase. However, their previous CFD software package had some limitations, such as not allowing for moving boundaries and only supporting single-phase simulations. With the increasing complexity of compressors, they needed a CFD solver capable of handling more complex physics. Thus, they turned to CONVERGE.

One of the big draws of CONVERGE was its autonomous meshing, which eliminates all manual meshing time and easily accommodates moving boundaries. CONVERGE’s novel Cartesian cut-cell approach produces a high-quality mesh that minimizes grid-related error. Furthermore, CONVERGE offers built-in fluid-structure interaction (FSI) modeling capabilities, including a 1D beam model ideal for simulating reed valves at a relatively low cost.

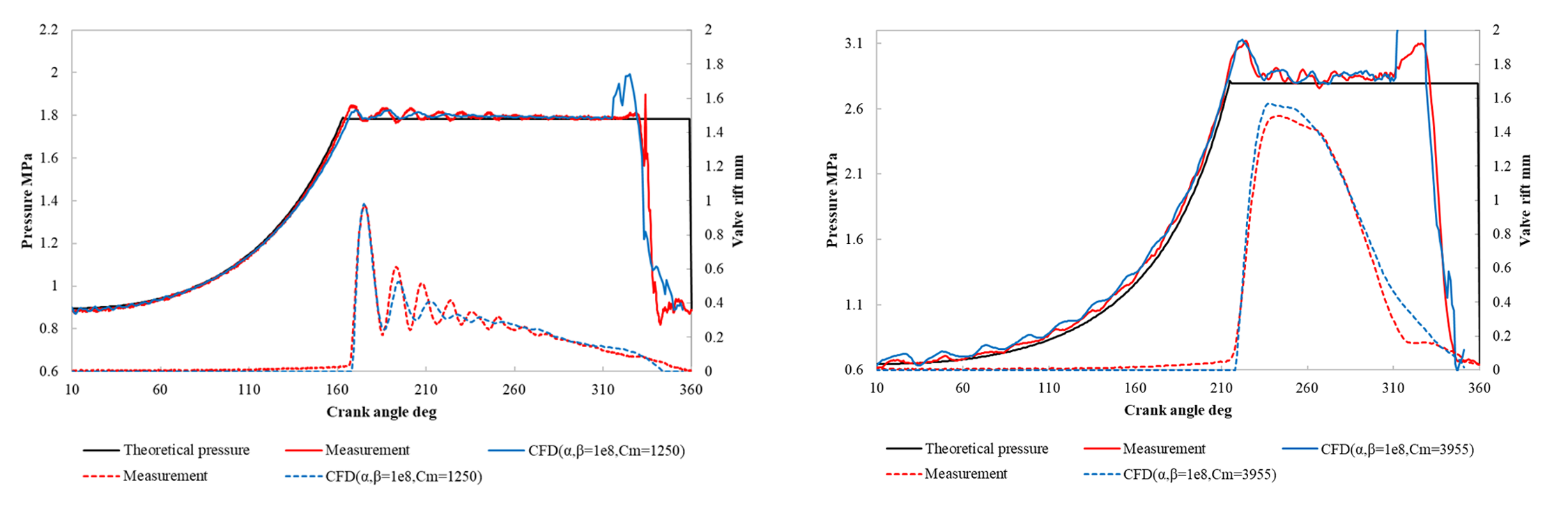

Daikin employed these features to validate that CONVERGE can accurately capture critical parameters including pressure and valve lift. They performed simulations for two different operating conditions: 28 rps and 110 rps.

Figure 2 shows the CONVERGE results for pressure and valve lift compared to experimental measurements for both operating conditions. The CONVERGE results indicate very good agreement in the pressure rise during compression, the pressure peak at valve opening, and the pressure fluctuation frequency and amplitude during the discharge event. In addition, the CONVERGE results demonstrate a valve opening timing very similar to the measurements, as well as the maximum valve lift, valve lift fluctuation frequency, and amplitude during the discharge event. The discrepancy that occurs around 310 crank angle degrees is most likely a result of the modeled gap flow at the point where the vane tip passes over the pressure transducer location.

Daikin Industries confirmed that CONVERGE can accurately simulate their swing compressor while also saving them a significant amount of time—upwards of two weeks per simulation. In addition, CONVERGE’s FSI modeling allows them to capture the motion of the swing compressor’s reed valve.

Next, Daikin plans to incorporate oil and phase change phenomena into their simulations to create a comprehensive model of their swing compressor. Ultimately, using CONVERGE will allow Daikin to account for the complex physics of their real-world compressor in their simulations to more effectively analyze and enhance the performance of their product.

Interested in using CONVERGE for your compressor simulations? Contact us today!

Kawabata, S., Deguchi, R., and Matsuura, H., “Calculation of Internal Flow in a Compressor With Valve Motion,” 26th International Compressor Engineering Conference at Purdue, West Lafayette, IN, United States, Jul 10–14, 2022.