Co-Author:

Elizabeth Favreau

Senior Marketing Communications Writer

Until a few years ago, I never thought much about diesel engines. In the United States, very few passenger cars have diesel engines, and while I was aware that they were used in vehicles like long-haul trucks, mostly I was just glad that I didn’t have to pay for the pricier diesel fuel when I filled my tank with gasoline.

It wasn’t until I started working at Convergent Science that I really considered how much of the world is powered by diesel engines. Not only are diesel cars more common in other countries, but diesel engines also enable trade, the distribution of goods, and the construction of new buildings and infrastructure by powering ships, trucks, and construction equipment. The diesel engine has been, and continues to be, instrumental in shaping society—pretty amazing, right?

However, working at Convergent Science, I also started to think more about emissions. Of course, I knew that reducing emissions from vehicles was incredibly important. But, I thought, isn’t that what electric cars are for? Now, electric cars make sense in certain sectors, but heavy-duty vehicles are a different story. Moving heavy-duty vehicles requires significant power, and today’s battery technology isn’t a practical solution. So what can we do to reduce emissions from heavy-duty vehicles while also ensuring that they can still perform their vital functions?

On the other side of the world from the Convergent Science World Headquarters, Annabelle Evans, an undergraduate at the University of New South Wales (UNSW), was considering this very problem. For her honors thesis project, she teamed up with Professor Evatt Hawkes and his research group to investigate a potential solution: hydrogen. I’ll turn it over to Annabelle to tell us about her research!

Co-Author:

Annabelle Evans

Undergraduate Researcher, University of New South Wales

Hydrogen is a promising alternative fuel for internal combustion engines. It is a carbon-free energy carrier and has the potential to be produced renewably. In addition, hydrogen has a superior energy density compared to batteries, making it an attractive option for heavy-duty applications.

However, if you just put hydrogen into a conventional compression ignition engine, you’re going to run into trouble. Hydrogen has a higher autoignition temperature than diesel, so it’s difficult to ignite hydrogen by compression alone. My research group is working on an engine that will use a little bit of diesel, which will ignite under compression, to act a bit like a match for the hydrogen.

Hydrogen-diesel dual-fuel engines are capable of being significantly cleaner and more efficient than traditional diesel engines, but careful consideration must go into their design. Hydrogen has a higher adiabatic flame temperature than diesel, which can lead to higher NOx emissions, and extreme temperatures can cause substantial heat losses, reducing the efficiency of the engine.

In order to design an optimal hydrogen-diesel dual-fuel engine, you need to understand the mechanisms driving the NOx emissions and heat losses. I set out to investigate these phenomena using computational fluid dynamics simulations. Simulations are cheaper and easier to run than experiments, and they give you more data than you can get experimentally. With my CONVERGE simulations, I could track the temperature, pressure, and mixture composition at many locations inside the engine.

I used CONVERGE’s detailed chemistry solver and high-fidelity emissions models to simulate a dual-fuel engine with different combinations of hydrogen and diesel [1]. I varied the hydrogen fraction from 0% to 90% and assessed the NOx emissions and heat losses for each condition. In my simulations, I assumed the hydrogen was evenly mixed with the air inside the cylinder when the diesel was injected at the top of the compression stroke.

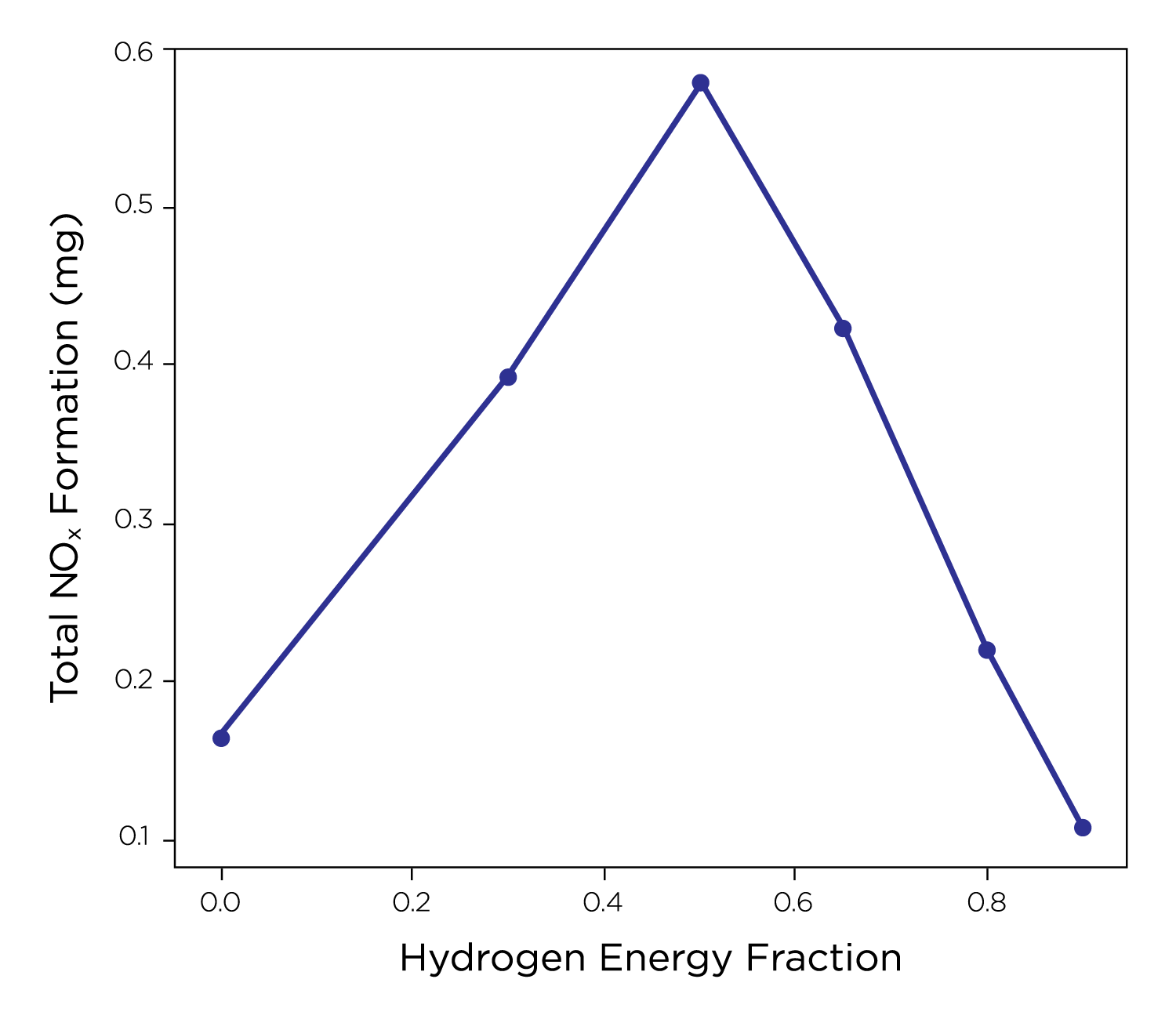

I found that NOx emissions varied with hydrogen fraction, as shown in Figure 1. After initially increasing, NOx emissions began to decrease as the hydrogen fraction grew to more than 50%.

We believe the reason that NOx emissions rise initially is because hydrogen’s high flame temperature increases the combustion temperature, which leads to more NOx formation. When you reach a certain level of hydrogen addition, however, you see the fuel and air mixing more evenly before combustion, which reduces the NOx emissions.

Our research group is also running experiments on the dual-fuel hydrogen engine concept, but they have not yet tested hydrogen fractions above 50%. However, these simulation results are a promising indicator that future experiments may show a decrease in NOx emissions with greater hydrogen fractions.

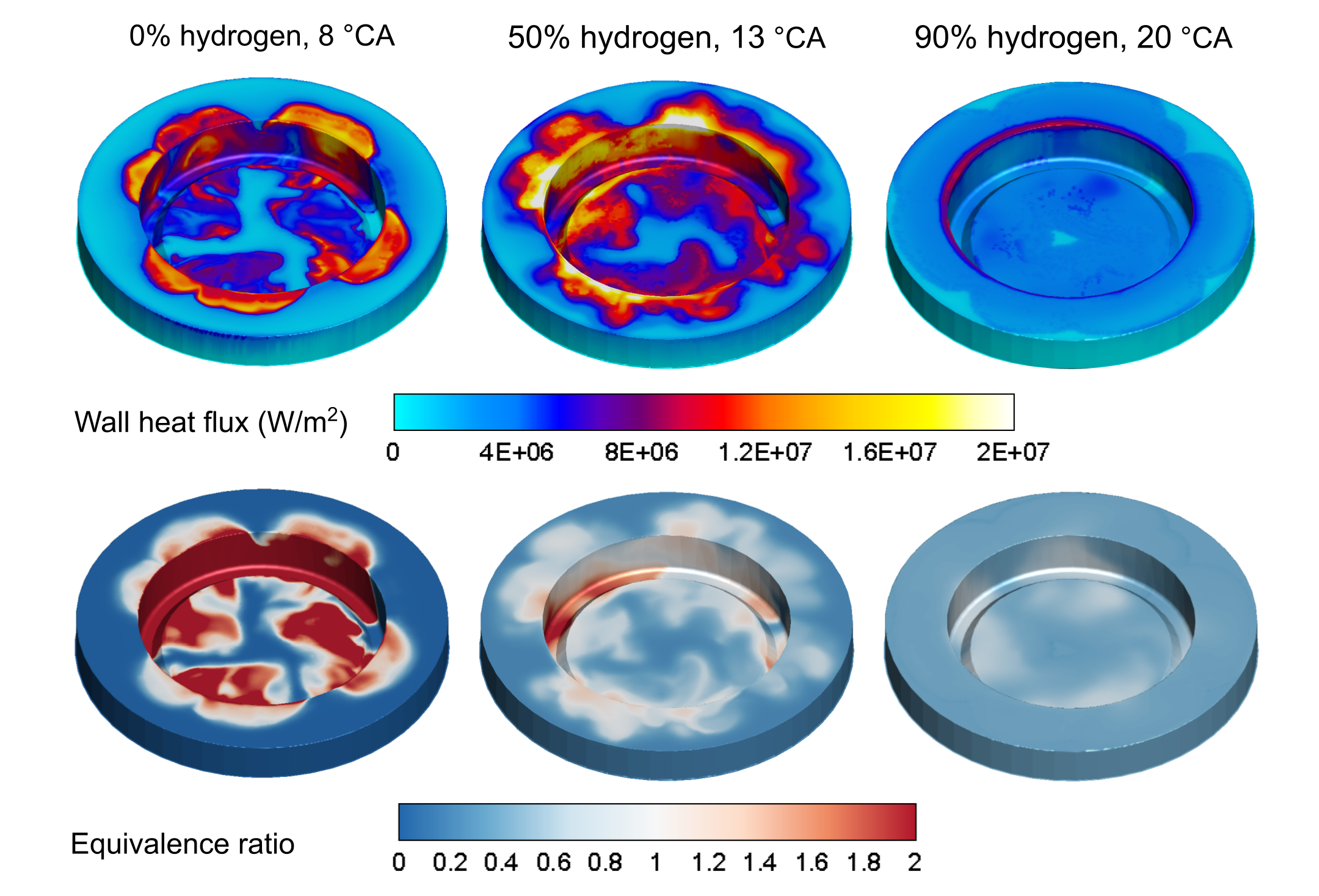

In terms of heat losses, I found that there were three main contributing factors: combustion phasing, the equivalence ratio near the cylinder walls, and turbulence. The heat transfer was concentrated primarily in a specific region around the edge of the piston, as you can see in Figure 2. Much of the injected diesel ends up in these regions, which causes high temperatures. In addition, the narrow “squish zone†above the piston rim generates turbulence, which promotes heat transfer.

Thanks, Annabelle! Understanding the reasons behind NOx emissions and heat loss is critical for designing highly efficient, low-emissions hydrogen engines. Annabelle’s data provides insight into the optimal ratio of hydrogen to diesel, as well as the information necessary to begin minimizing heat losses and NOx emissions. Hydrogen offers a path to greener heavy-duty vehicles, and Annabelle’s research brings us one step closer to a cleaner transportation future.

To learn more about Annabelle’s research, check out her SAE paper here!

The CONVERGE Academic Program empowers students, professors, and academic researchers around the world to advance science and technology. Convergent Science offers exclusive CONVERGE license deals for academic research, along with free support, training, and resources. Academic researchers are leveraging CONVERGE’s unique capabilities to study everything from gas turbines and internal combustion engines to wind turbines and heart valves. Learn more!

[1] Evans, A., Wang, Y., Wehrfritz, A., Srna, A., Hawkes, E., Liu, X., Kook, S., and Chan, Q.N., “Mechanisms of NOx Production and Heat Loss in a Dual-Fuel Hydrogen Compression Ignition Engine,” SAE Technical Paper 2021-01-0527, 2021. DOI: 10.4271/2021-01-0527