Author:

Erik Tylczak

Senior Research Engineer

On July 16th, I will look up at the night sky and celebrate the 50-year anniversary of the launch of Apollo 11. As I admire the full moon, the CFDer in me will think about the classic metaphor of the three-legged stool. Modern engineering efforts depend on theory, simulation, and experiment: Theory gives us basic understanding, simulation tells us how to apply this theoretical understanding to a practical problem, and experiment confirms that our applied understanding is in agreement with the physical world. One element does not seek to replace another; instead, each element reinforces the others. By modern standards, simulation did not exist in the 1960s—NASA’s primary “computers” were the women we saw in Hidden Figures, and humans are limited to relatively simple calculations. When NASA sent people to the moon, it had to build a modern cathedral balanced atop a two-legged stool.

I like the cathedral metaphor for the Saturn V rocket because it expresses some unexpected similarities between the efforts. A medieval cathedral was a huge, societal construction effort. It required workers from all walks of life to contribute above and beyond, not just in scale but in care and diligence. Designers had to go past what they fully understood, overcoming unknown engineering physics through sheer persistence. The end product was a unique and breathtaking expression of craftsmanship on a colossal scale.

In aerospace, we are habituated to assembly lines, but each Saturn V was a one-off. The Apollo program as a whole employed some 400,000 people, and the Saturn family of launch vehicles was a major slice of the pie. Though their tools were certainly more advanced than a medieval artisan’s, these workers essentially built this 363-foot-tall rocket by hand. They had to, because the rocket had to be perfect. The rocket had to be perfect because there was so little margin for error, because engineers were reaching so far beyond the existing limits of understanding. Huge rockets are not routine today, but I want to highlight a few design challenges of the Saturn V as places where modern simulation tools would have had a program-altering effect.

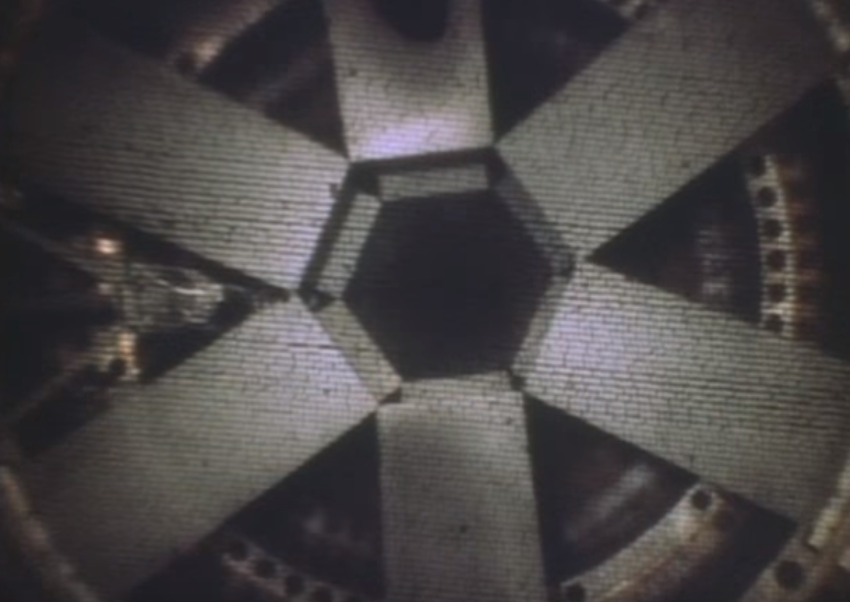

The mighty F-1 remains the largest single-chambered liquid-fueled rocket engine ever fired. All aspects of the design process were challenging, but devising a practical combustion chamber was particularly torturous. Large rocket engines are prone to a complex interaction between combustion dynamics and aeroacoustics. Pressure waves within the chamber can locally enhance the combustion rate, which in turn alters the flow within the engine. If these physical processes occur at the wrong rates, the entire system can become self-exciting and unstable. From a design standpoint, engineers must control engine stability through chamber shaping, fuel and oxidizer injector design, and internal baffling.

Without any way to simulate the fuel injection, mixing, combustion, and outflow, engineers were left with few approaches other than scaling, experimentation, and doggedness. They started with engines they knew and understood, then tried to vary them and enlarge them. They built a special 2D transparent thrust chamber, then applied high-speed photography to measure the unsteadiness of the combustion region. They literally set off tiny bombs within an operating engine, at a variety of locations, monitoring the internal pressure to see whether the blast waves decayed or were amplified. Eventually they produced a workable design for the F-1, but, in the words of program manager Werner von Braun:

…lack of suitable design criteria has forced the industry to adopt almost a completely empirical approach to injector and combustor development… [which] does not add to our understanding because a solution suitable for one engine system is usually not applicable to another…

It was being performed by engineers, but in some senses, it wasn’t quite engineering. Persistence paid off in the end, but F-1 combustion instability almost derailed the whole Apollo program.

Imagine if Rocketdyne engineers had had access to modern simulation tools! A tool like CONVERGE can simulate liquid fuel spray impingement directly, allowing an engineer to parametrically vary the geometry and spray parameters. A tool like CONVERGE can calculate the local combustion enhancement of impinging pressure fluctuations, allowing an engineer to introduce different baffle shapes and structures to measure their moderating effect. And the engineer can, in von Braun’s words, add to his or her understanding of how to combat combustion instability.

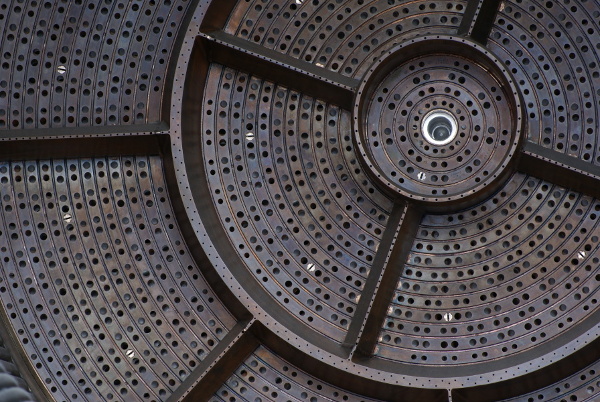

Fuel slosh in the colossal lower-stage tanks presented another design challenge. The first-stage liquid oxygen tank was 33 feet in diameter and about 60 feet long. How do you study slosh in such an immense tank while subjecting it to what you think will be flight-representative vibration and acceleration? What about the behavior of leftover propellant in zero gravity? In the 1960s, the answer was you built the rocket and flew it! In fact, the early Saturn launches (uncrewed, of course) featured video cameras to monitor fuel flow within the tanks. Cameras of that era recorded to film, and these cameras were housed in ejectable capsules. After collecting their several minutes of footage, the capsules would deploy from the spent stage and parachute to safety. I bet those engineers would have been over the moon if you had presented them with modern volume of fluid simulation tools.

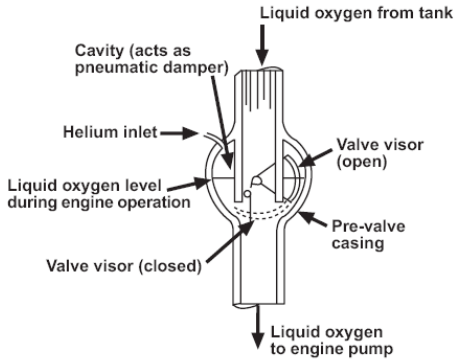

Readers who have watched Apollo 13 may recall that the center engine of the Saturn V second stage failed during the launch. This was due to pogo, another combustion instability problem. In a rocket experiencing pogo, a momentary increase in thrust causes the rocket structure to flex, which (at the wrong frequency) can cause the fuel flow to surge, causing another self-exciting momentary increase in thrust. In severe cases, this vibration can destroy the vehicle. Designers added various standpipes and accumulators to de-tune the system, but this was only performed iteratively, flying a rocket to measure the effects. Today, we can study the fluid-structure interaction before we build the structure! Modern simulation tools are dramatic aids to the design process.

Today’s aerospace engineering community is doing some amazing things. SpaceX and Blue Origin are landing rockets on their tails. The United Launch Alliance has compiled a perfect operational record with the Delta IV and Atlas V. Companies like Rocket Lab and Firefly Aerospace are demonstrating that you don’t need to have the resources of a multinational conglomerate to put payloads into orbit. But for me, nothing may ever surpass the incredible feat of engineers battling physical processes they didn’t fully understand, flying people to the moon on a two-legged stool.

Interested in reading more about the Saturn V launch vehicle? I recommend starting with Dr. Roger Bilstein’s Stages to Saturn.