Author:

Sankalp Lal

Application Engineer, Documentation and Technical Marketing

Significant cycle-to-cycle variations (CCV) in internal combustion (IC) engines can lead to undesirable effects like noise and vibration, engine damage, and poor drivability. It is important for engineers to estimate quantities such as peak cylinder pressure, combustion duration, and coefficient of variance of indicated mean effective pressure (IMEP) to design better engines. Moderating CCV can open doors to many advanced combustion concepts, such as low-temperature combustion strategies, to reduce emissions and increase efficiency.

To accurately estimate CCV, you need to perform many engine cycle simulations—on the order of 100 consecutive cycles. Typically, simulating one engine cycle that follows our recommended best practices in CONVERGE takes a few hours with sufficient computational resources. Continuing that simulation for 100 consecutive cycles is a painstaking process (on the order of a few months) and hence a computationally expensive one.

Is there an alternate method to capture CCV?

The answer is yes! We know that long runtimes are unacceptable for many industry research timelines, and so we have applied an alternate method, called the concurrent perturbation method (CPM), to capture CCV in CONVERGE. This method was first proposed and published by Ameen et al. (2016)1 at Argonne National Laboratory.

What is the concurrent perturbation method?

Instead of solving 100 cycles consecutively, with CPM, CONVERGE solves 100 cycles concurrently. Given sufficient computational resources, CPM reduces the overall turnaround time to the time taken to simulate one engine cycle. At this point, you might be asking yourself how it is possible to run the cycles concurrently when the result of one cycle can be determined only after knowing the results of the cycle preceding it.

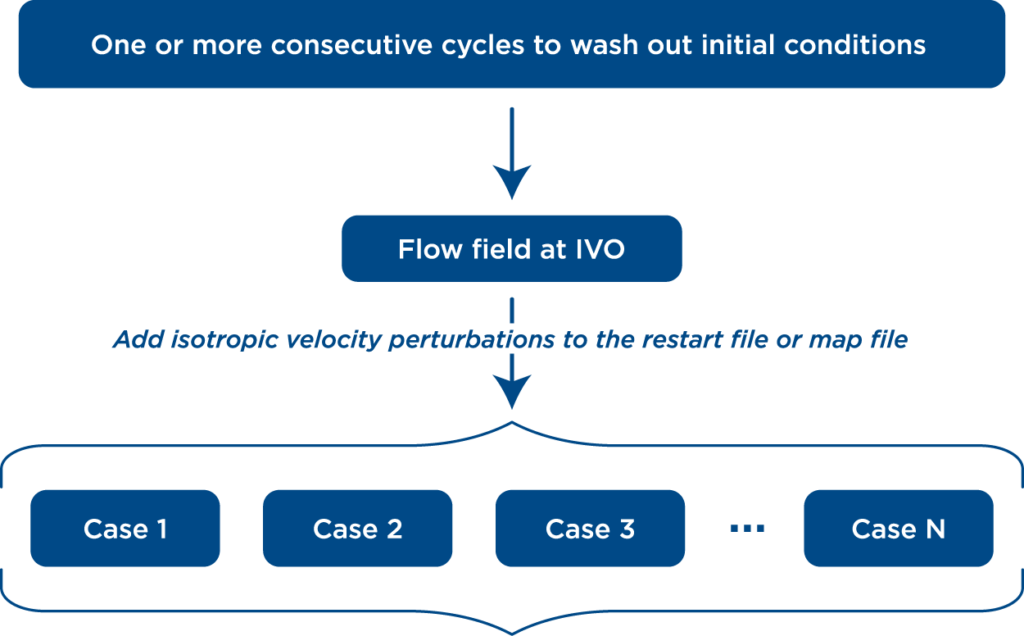

This is where the perturbation in CPM comes into play. We start by simulating one or more engine cycles to wash out the homogenized initial conditions that are defined while setting up the case. The combustion event and exhaust process of the first cycle(s) produces a representative velocity, pressure, temperature, and species field. The outcome of the initial cycle(s) is used to initialize each of the concurrent cycles, which are set up as independent cases. Each individual cycle’s flow field is then perturbed in order to yield a distinct cycle as the simulation proceeds (Figure 1). We apply only a miniscule perturbation to each flow field so as to not significantly change it. The perturbation is simply a noise field applied on top of the velocity field. The solution naturally develops into a different realization due to the chaotic nature of the combustion system.

What do the results show?

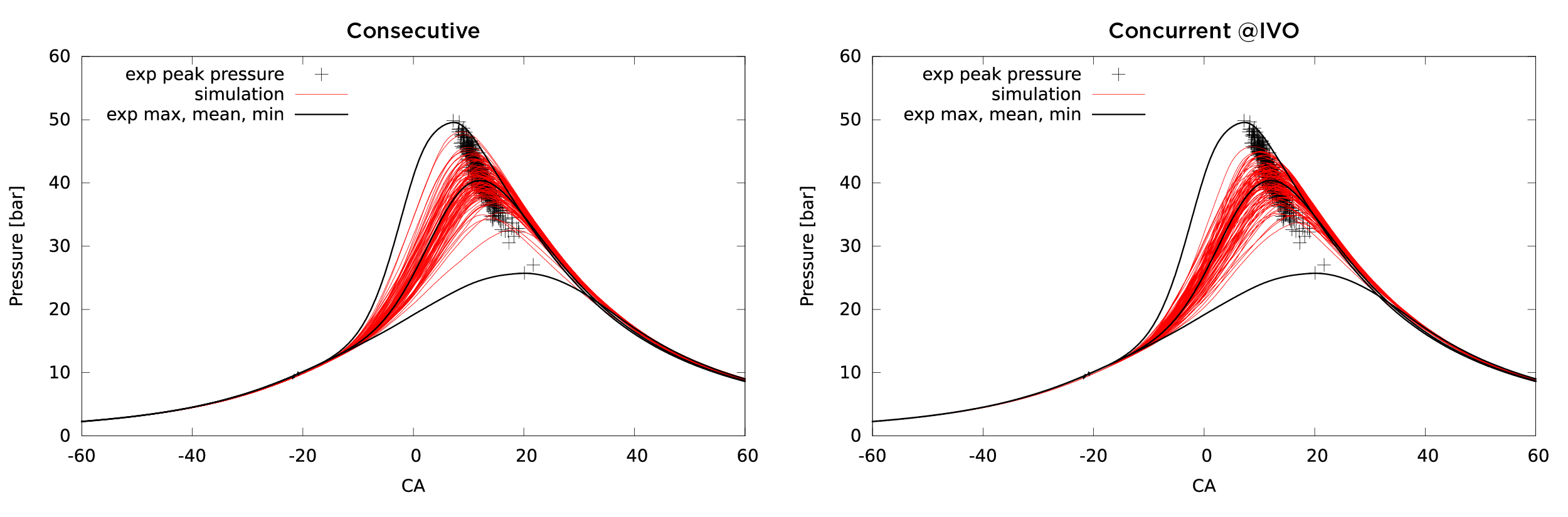

Figure 2 shows a comparison of the cylinder pressure obtained from consecutively and concurrently run simulations performed by Probst et al. (2020).2 The results are similar, and the predicted pressure lies within the maximum and the minimum pressure cycle of the measured data.

Additionally, Probst et al. found that starting the concurrent cycle simulations at intake valve opening (IVO) is sufficient to yield distinct and valid cycles. In contrast, when running cycles consecutively, it is necessary to simulate the full cycle. The required core hours for concurrently run cycles, as a result, are fewer than for consecutively run cycles. So, by concurrently running cases, multiple engine cycles can be completed in far less wall-clock time and with fewer core-hours compared to consecutive simulations.

Are you ready to try CPM to speed up your projects? Check out the video below to learn how CPM works, how to set up CPM in CONVERGE, and the conditions in which it will work best.

References

[1] Ameen, M., Yang, X., Kuo, T., and Som, S., “Parallel methodology to capture cyclic variability in motored engines”, International Journal of Engine Research, 18(4), 366-377, 2016. DOI: 10.1177/1468087416662544

[2] Probst, D., Wijeyakulasuriya, S., Pomraning, E., Kodavasal, J., Scarcelli, R., and Som, S., “Predicting Cycle-to-Cycle Variation With Concurrent Cycles In A Gasoline Direct Injected Engine With Large Eddy Simulations”, Journal of Energy Resources Technology, 142(4), 2020. DOI: 10.1115/1.4044766