Author:

Erik Tylczak

Senior Research Engineer

When you purchase software, there are often many resources to bring you up to speed on its use and application for your industry—manuals, online tutorials, YouTube videos. How often, though, will the software vendor be available to work directly with you to optimize that software for your particular problem? Is it typical for the software vendor to have detailed knowledge not just of their product, but the particular problem you are trying to solve? How often will that vendor offer that detailed, industry-specific knowledge to help you use their software to solve a problem?

At Convergent Science, we not only supply our customers with our innovative CONVERGE CFD software, we work directly with our clients to help them apply CONVERGE in the most effective way to their particular engineering problems. By combining our deep knowledge of our software and of computational fluid dynamics in general with our clients’ understanding of their specific problems, we truly can solve the hard problems.

We at Convergent Science see long-term engineering collaborations with our clients as an indispensable part of our core product. It helps our users generate better results, and it helps our developers and applications engineers improve the modeling capabilities available in CONVERGE. Nearly half of our engineers work on the applications team, which directly supports our users. If you’re thinking about taking the plunge, you’ll be doing so hand-in-hand with subject matter experts in combustion modeling, numerical methods, practical engine development, and a myriad of other relevant topics.

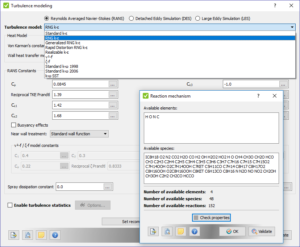

Take, for example, a scenario where you, as a user, are faced with choosing the best physical models for the use in your simulation. It is a CFD truism that you must select appropriate numerics according to the physics, or you will generate physics based on your selection of numerics. That’s not wrong, but it’s not always very helpful. When you set up your case, you might need to choose one of a dozen turbulence models, one of two dozen flux limiter functions, one of more reaction mechanisms than I care to name… the design space is vast. CONVERGE’s example cases are a great starting point, but they may not address the subtleties of your specific case. It’s probably not practical for an organization or user to explore every last combination of case setup parameters, but that’s our bread and butter. With their detailed knowledge of this parameter space, our applications engineers can quickly guide you through case setup and help you select the most appropriate settings and models.

Take, for example, a scenario where you, as a user, are faced with choosing the best physical models for the use in your simulation. It is a CFD truism that you must select appropriate numerics according to the physics, or you will generate physics based on your selection of numerics. That’s not wrong, but it’s not always very helpful. When you set up your case, you might need to choose one of a dozen turbulence models, one of two dozen flux limiter functions, one of more reaction mechanisms than I care to name… the design space is vast. CONVERGE’s example cases are a great starting point, but they may not address the subtleties of your specific case. It’s probably not practical for an organization or user to explore every last combination of case setup parameters, but that’s our bread and butter. With their detailed knowledge of this parameter space, our applications engineers can quickly guide you through case setup and help you select the most appropriate settings and models.

Here’s one example. A leading European automotive manufacturer had transitioned to CONVERGE. They were simulating NOx formation in a diesel engine, using the same physical models as they’d always used. Agreement with experimental measurements was, in a word, poor. Convergent Science applications engineers identified some case setup improvements, using physical models that the client was aware of but had never tested.

These setup improvements weren’t limited to maximizing out-of-the-box performance. They were a joint research effort. Convergent Science engineers applied real engineering knowledge to the problem. While running the client’s case on our local systems, Convergent Science engineers developed a hybrid reduced-order chemical mechanism for the client to improve the NOx formation prediction, without requiring a large and expensive mechanism set. Several setup iterations later, the simulated emissions were within the measurement tolerances of the experiment. The result of this collaboration was that the client had a predictive case setup that they applied to further studies, and Convergent Science had an improved chemistry mechanism that had been validated with experimental data.

The collaboration doesn’t end once the case is running. Because our engineers are highly experienced with and knowledgeable about both the numerical underpinnings of the software and with engine design, they can also help you interpret and understand the results.

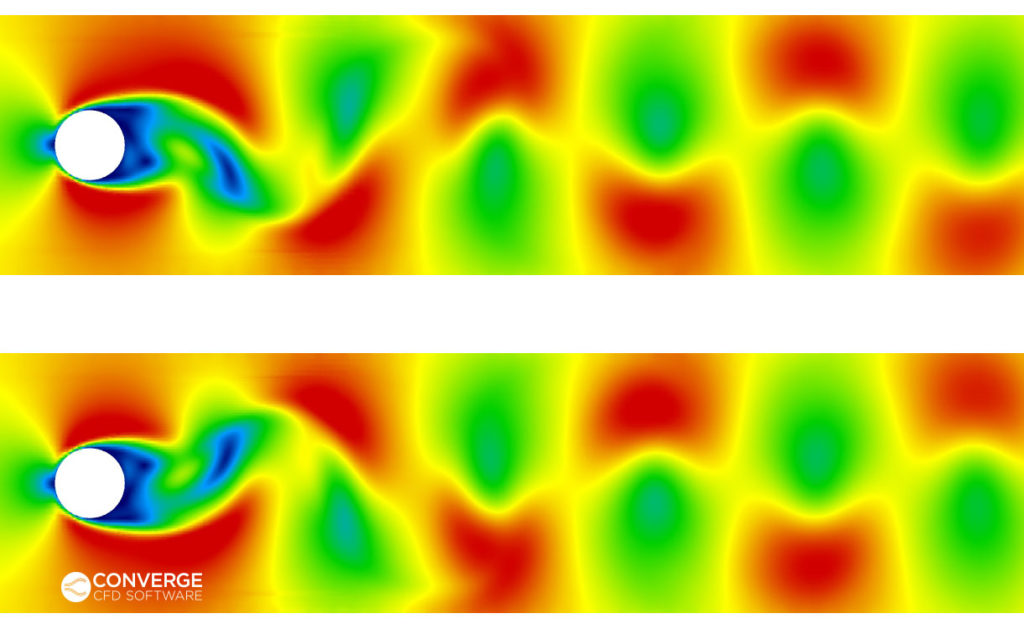

For example, consider von Karman vortex shedding from a cylinder. Depending on tiny variations in the actual running of the case (different partitioning, machine truncation error, etc.), there will be a phase difference between two shedding cases. Which result is correct? Both, of course, are valid solutions of the Navier-Stokes equations. Both are correct. Complex engine simulations can display similar behavior (cycle-to-cycle variability), and our experienced and knowledgeable applications engineers can help you understand what you might be seeing. Sometimes what looks like the result of a setup error is physically correct and operationally important.

We see our applications team’s work as part of a true partnership, not just good customer support. The best way to improve our software and our understanding of challenging problems is to use our software to solve those problems! Every time we see simulated results trace through experimental data points, that’s another validation case. The aforementioned hybridized reduced-order chemical mechanism is a mechanism that we now recommend to clients as an example case. Our developers and applications engineers all benefit from this collaboration.

At Convergent Science, we don’t think of ourselves as your CFD vendor. We’re your CFD partner. Want to learn more? Please check out our Customer Experience page and don’t hesitate to get in touch.