Author:

Sarani Rangarajan

Senior Research Engineer

The United States Environmental Protection Agency (US EPA) has strict standards to control the emissions polluting the air. The latest tier 3 standards are set to start from 2017 and immediately require a lower sulfur content in gasoline. These new regulations will apply to most vehicles on the road, barring only some heavy-duty vehicles. As a consequence of the new tier of regulations, the US EPA expects a significant reduction in emissions by 2030, including almost an 8000-ton reduction in fine particulate matter levels (PM 2.5). These regulations will bring the US on par with California, Europe, and South Korea.

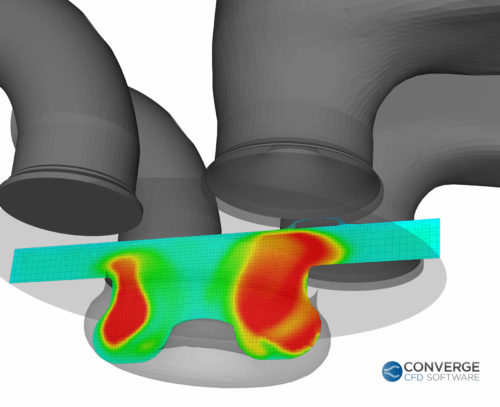

If we want to protect our environment and our lungs (or sell cars, for that matter), we must learn to adapt existing systems to work more efficiently and comply with regulatory bodies. CONVERGE CFD can simulate the fundamental physical and chemical processes involved in the various stages of soot formation (particle inception, coagulation, condensation, and soot surface reactions). You can use empirical and phenomenological models to quickly estimate emissions. For a more detailed and accurate simulation of soot formation, CONVERGE leverages the SAGE detailed chemistry solver in two detailed soot models. Note that the SAGE solver requires a detailed mechanism that includes PAH chemistry. To make things easier for you, CONVERGE contains a tool for mechanism merging that can combine two mechanisms.

Detailed soot modeling is applicable for a wide range of conditions and provides a host of data (including soot mass, number density, volume fraction, soot diameters, and surface area). Both of the CONVERGE detailed soot models are two-way coupled with the gas phase, meaning that soot formation affects gas phase chemistry and heat release, and vice versa. The two-way coupling means that your simulations results will provide a complete and accurate picture of soot formation as well as combustion.

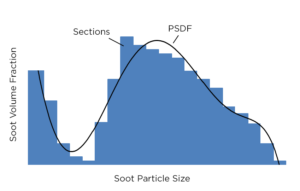

The first detailed soot model, the Particulate Mimic (PM) model, uses the method of moments while the second, the Particulate Size Mimic (PSM) model, is based on sectional methods in which the solution is  obtained by solving sections (i.e., bins) that contain particles of a similar size. The primary difference between the two is that the former assumes a particle size distribution function whereas the latter determines the particle size distribution in addition to the PM outputs.

obtained by solving sections (i.e., bins) that contain particles of a similar size. The primary difference between the two is that the former assumes a particle size distribution function whereas the latter determines the particle size distribution in addition to the PM outputs.

CONVERGE Studio makes setting up these detailed models for complex soot formation and oxidation processes straightforward. To ensure that your PM and PSM simulations are as efficient as possible, CONVERGE includes acceleration strategies including multizone modeling and dynamic mechanism reduction. At the end of the day, the industry is moving toward a whole-system approach for simulating engines. No longer can we disconnect exhaust and emissions from combustion, since we don’t have the margin to accept the errors introduced by separate simulations. Even the US EPA considers the fuel and the vehicle a single integrated system. For accurate combustion and downstream simulation, it makes sense to use a single detailed chemistry solver to address the increasingly strict emissions challenges.