Author:

Sarani Rangarajan

Senior Research Engineer

One of the more controversial subjects we talk about here at Convergent Science is the role of turbulence-chemistry interaction (TCI) when using our SAGE detailed chemistry solver.

TCI is used to describe two separate but linked processes: enhanced mixing in momentum, energy, and species due to turbulence and the commutation error in the reaction rate evaluation. A good turbulence model should always account for the enhanced mixing due to turbulence.

The commutation error is more difficult to address. In an LES simulation, the commutation error is the difference between evaluating the reaction rates using the spatially filtered quantities and using the un-filtered quantities (the latter is exact and the former is an approximation) and then filtering the reaction rates. It is usually convenient to use the averaged or filtered values to evaluate the reaction rates, which unfortunately means more error. For LES, the commutation error reduces as the cell size is reduced[1], and thus, with sufficient grid resolution, the commutation error becomes negligible.

In this blog post, we briefly describe a study that demonstrates that with sufficient grid resolution, CONVERGE CFD (with LES and detailed chemistry) can resolve the enhanced mixing due to turbulence without explicitly assigning a sub-grid model for the commutation error. For more details, please see the accompanying white paper.

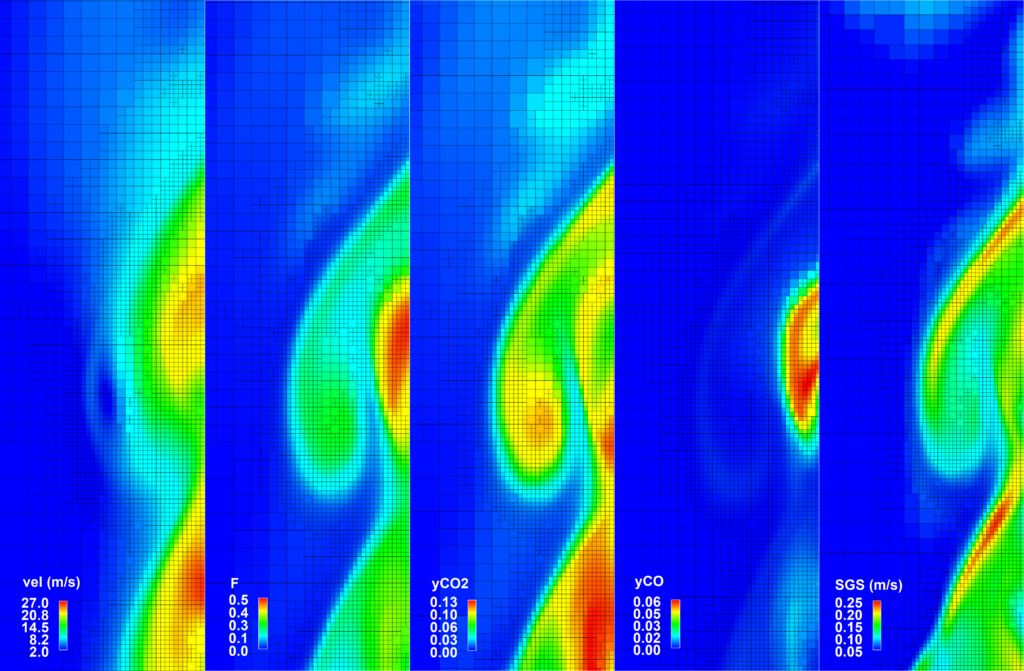

We simulate a canonical turbulent partially premixed flame, Sandia Flame D. We leverage Adaptive Mesh Refinement (AMR) and adaptive zoning as acceleration strategies to speed up the computationally expensive LES simulations. Figure 1 shows the fine resolution around a subsection of the flame due to AMR, which allows us to get good resolution when and where we need it.

We first conduct grid convergence studies and find that 0.25 mm minimum grid size is sufficient to resolve most of the velocity and species fluctuations.

Then, we demonstrate that the commutation error becomes smaller and we resolve more velocity and species fluctuations as we use finer meshes. With the finest mesh, we match not only the the mean and RMS to the experimental value, but also the conditional mean and the shape of joint probability distribution function.

Finally, we take on the challenge of accurately predicting of non-equilibrium combustion processes. These processes (i.e., extinction and reignition) are dependent on two factors:

We compare thousands of data points from experiments to the equivalent points from the LES to determine that CONVERGE correctly predicts the extinction and reignition trends.

The SAGE detailed chemistry solver with LES has demonstrated success in a host of applications[2,3,4,5,6], including gas turbines and internal combustion engines.

We show in this white paper that when you resolve most of the velocity and species fluctuations and significantly reduce the commutation error, you can predict mixing-controlled turbulent combustion without a model for the commutation error in the reaction rates.

CONVERGE contains multiple acceleration strategies that make SAGE detailed chemistry + LES a reasonable strategy as far as computational costs go. Ready to dive more in-depth? Our TCI white paper is waiting for you!

[1] Davidson, L., “Fluid mechanics, turbulent flow and turbulence modeling,” Chalmers University, 2018. www.tfd.chalmers.se/~lada/postscript_files/solids-and-fluids_turbulent-flow_turbulence-modelling.pdf

[2] Drennan, S.A., and Kumar, G., “Demonstration of an Automatic Meshing Approach for Simulation of a Liquid Fueled Gas Turbine with Detailed Chemistry,” 50th AIAA/ASME/SAE/ASEE Joint PropulsionConference, AIAA 2014-3628, Cleveland, OH, United States, July 28-30, 2014. DOI:10.2514/6.2014-3628

[3] Kumar, G., and Drennan, S., “A CFD Investigation of Multiple Burner Ignition and Flame Propagation with Detailed Chemistry and Automatic Meshing,” 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Propulsion and Energy Forum, AIAA 2016-4561, Salt Lake City, UT, United States, July 25-27, 2016. DOI:10.2514/6.2016-4561

[4] Yang, S., Wang, X., Yang, V., Sun, W., and Huo, H., “Comparison of Flamelet/Progress-Variable and Finite-Rate Chemistry LES Models in a Preconditioning Scheme,” 55th AIAA Aerospace Sciences Meeting, AIAA SciTech Forum, AIAA 2017-0605, Grapevine, TX, United States, January 9-13, 2017. https://doi.org/10.2514/6.2017-0605

[5] Pei, Y., Som, S., Pomraning, E., Senecal, P.K., Skeen, S.A., Manin, J., Pickett, L.M., “Large Eddy Simulation of a Reacting Spray Flame with Multiple Realizations under Compression Ignition Engine Conditions,” Combustion and Flame, 162, 4442-4455, 2015. DOI:10.1016/j.combustflame.2015.08.010

[6] Liu, S., Kumar, G., Wang, M., and Pomraning, E., “Towards Accurate Temperature and Species Mass Fraction Predictions for Sandia Flame-D using Detailed Chemistry and Adaptive Mesh Refinement,” 2018 AIAA Aerospace Sciences Meeting, AIAA SciTech Forum, AIAA 2018-1428. DOI:10.2514/6.2018-1428.