Author:

Elizabeth Favreau

Marketing Writing Team Lead

Many entrepreneurs dream of creating a product that will revolutionize an industry. Starting off with an idea and a vision, only a small fraction manage to bring their dream to fruition. Sometimes, however, equipped with the right tools and a solution to a pressing need, an entrepreneur can transform an industry and usher in a new era of technology.

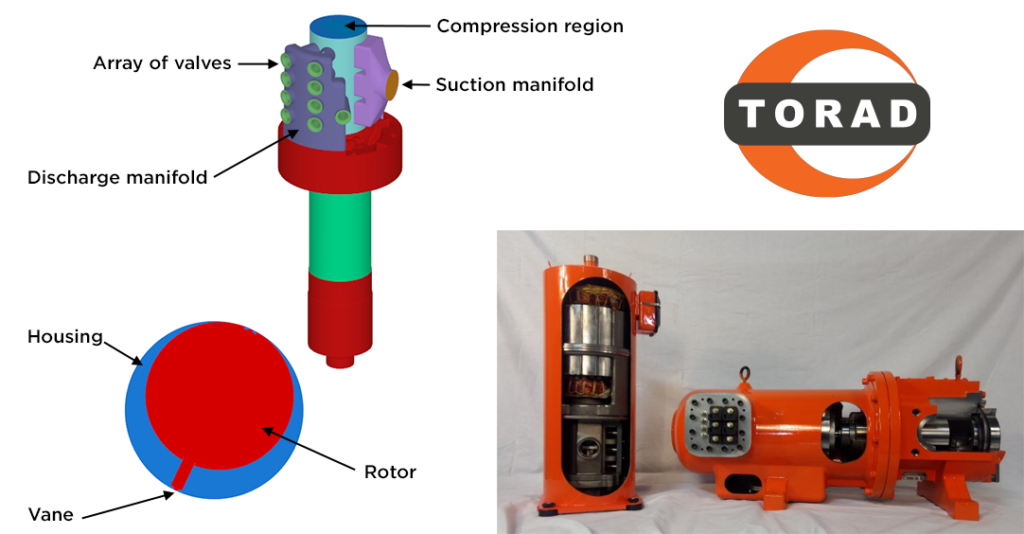

Working in the HVAC industry, Greg Kemp, founder and CEO of TORAD Engineering, together with partner Joe Orosz, a veteran HVAC compressor engineer, saw room for improvement: many compressors were overly complex and difficult to manufacture. They had a solution: create a new compressor technology that was simpler, lower cost, and easier to manufacture—a compressor that would simultaneously help shift the industry to low-global warming potential (GWP) refrigerants. The technology? A spool compressor.

“The spool compressor is a high-displacement-density machine for ultra-low GWP refrigerants,” Greg said. “The spool compressor provides a lower cost and higher efficiency alternative than legacy technologies for use in the 10–100 hp range with medium-pressure, ultra-low GWP refrigerants.”

Greg set out to create a compressor with a simple, compact design, consisting of only a few major components to reduce the complexity and manufacturing costs. At the same time, he wanted his design to be highly scalable to broaden its applicability across capacity ranges. Figure 1 shows the spool compressor he invented.

For the next step in creating a revolutionary compressor, the team at TORAD wanted to optimize their design for maximum efficiency and ensure its compatibility with low-pressure, ultra-low-GWP refrigerants. This is where having the right tools comes into play.

Computational fluid dynamics (CFD) is a powerful tool for compressor design. CFD saves you time and money by allowing you to virtually test different designs before building a physical prototype. You can gain insight into global parameters including mass flow rate and power consumption, and analyze noise, vibration, thermal design, and leakage. With fully autonomous meshing, CONVERGE CFD software significantly simplifies the case setup process, enabling an even faster turnaround on results.

“We use CONVERGE extensively for modeling the compression process, specifically trying to maximize the efficiency,” Greg said.

For their simulation studies, Greg and his team focused on the compressor geometry and the discharge process, which is regulated by an array of valves. The CONVERGE simulations revealed some previously unknown flow losses that occurred when the vane tip passed over the valves.

“Working with the CONVERGE team and modeling our valves, we were able to come up with a configuration that would offer a significant improvement in the efficiency of the machine because of the improved valve operation,” Greg said.

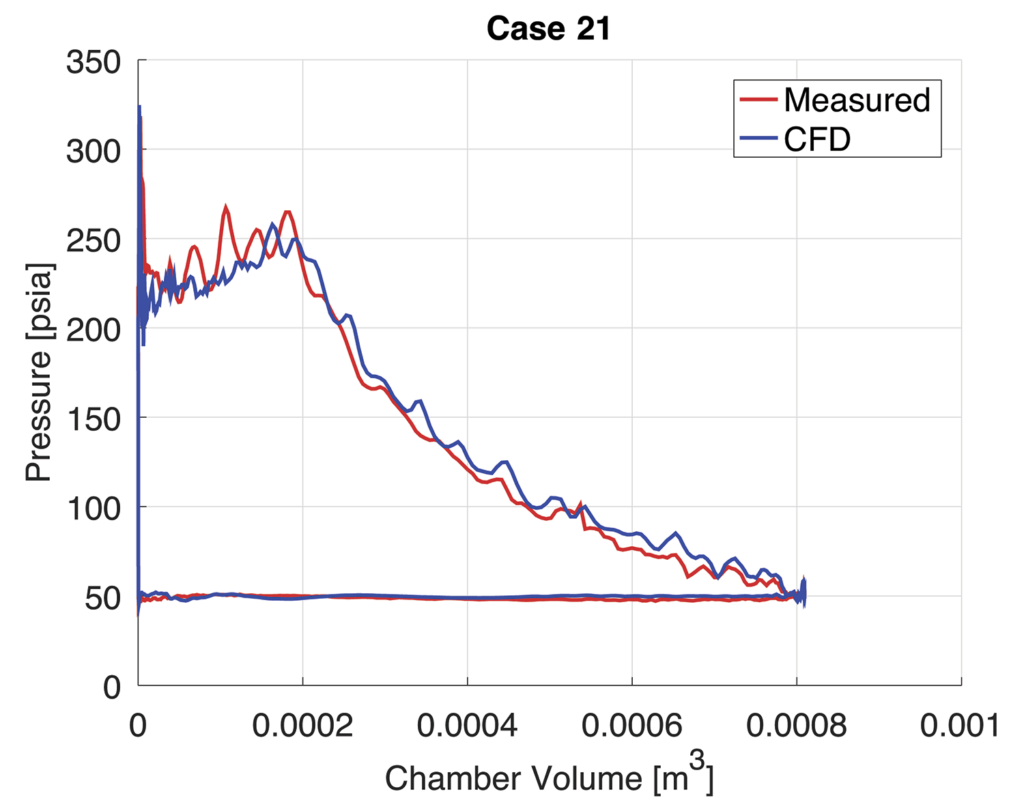

The engineers at TORAD built a couple of prototypes to test the new valve configuration. The experimental results matched well with the CFD predictions, confirming an increase in efficiency.

“Those gains actually put us in a position to meet critical market hurdles relative to performance utilizing the low-GWP refrigerant R1234ze,” Greg said.

Greg’s journey with CONVERGE began when the TORAD team was looking for a CFD solver to help them analyze their spool compressor design. After researching CFD vendors, TORAD selected two companies, Convergent Science being one of them, to conduct benchmark studies. Both software packages replicated the experimental results to their satisfaction, but they were also evaluating another critical factor: usability.

“We determined that it was just a lot easier to go about setting up CONVERGE than anything else we saw,” Greg said.

TORAD settled on CONVERGE as their CFD software of choice, and Greg began the process of learning how to use it. He worked closely with the Convergent Science Applications team, meeting with them up to 2–3 times per week.

“They were so good and so responsive at sitting down with me and working through issues and explaining things where I had questions,” Greg said. “It was not typical of what I’ve seen with other software packages. There was no shortage of time they were willing to spend. There was no clock running, ticking off how many hours I’m using.”

After about three months of regular training and support sessions, Greg was able to set out on his own and run simulations by himself. Greg will tell you that he’s not a CFD expert, but with CONVERGE, he’s able to create a case setup template that makes it, if not trivial, at least straightforward to set up a new simulation.

In addition to the relatively simple case setup, TORAD has been pleased with how well the CONVERGE results match the experimental data for critical parameters (e.g., localized pressures, overall efficiency, and volumetric efficiency). The plot in Figure 2 shows an example of measured pressure values versus the simulation results.

Incorporating CFD into their development workflow, the team at TORAD has achieved some impressive improvements to their already impressive technology.

“It’s not an over-exaggeration to say that we owe the success we’ve had over the last year in obtaining higher efficiency results to the work we’ve done with CONVERGE,” Greg said. “CONVERGE is a strategic development tool for TORAD. We are now able to model and evaluate ideas and optimize configurations before building hardware, which saves us time and money.”

TORAD’s spool compressor is still in development, with production expected to begin in the next couple of years. The team is currently working on modeling their spool compressor with ultra-low GWP refrigerants like R1234ze. If the results they’ve seen during the development phase are any indication, the spool compressor is going to make a big splash (with little carbon footprint) when it hits the market.

To learn more about how CONVERGE was used to simulate the TORAD spool compressor, register for our upcoming webinar!