Author:

Elizabeth Favreau

Marketing Writing Team Lead

Emissions regulations around the globe are becoming increasingly stringent. To design compliant internal combustion (IC) engines, optimizing every component of the engine is key and every small gain in efficiency counts. Since their invention more than a century ago, IC engines have come a long way. Today’s IC engines are advanced technologies, but there’s still room for improvement—and new, innovative methods can help us achieve those improvements more efficiently.

Convergent Science, Polaris, and Oracle Cloud teamed up to put some of the latest technologies to the test, combining machine learning (ML), high-performance computing, and computational fluid dynamics (CFD) for a geometry optimization study. The team was led by Jacob Hanson, Senior Powertrain CFD Engineer at Polaris, Dan Probst, Senior Principal Engineer at Convergent Science, and Arnaud Froidmont, HPC Solution Architect at Oracle Cloud.

To test this methodology, the team tackled a relatively simple exhaust port optimization. As Jacob says: “Every engine has an exhaust port, and every engine needs an optimized exhaust port.”

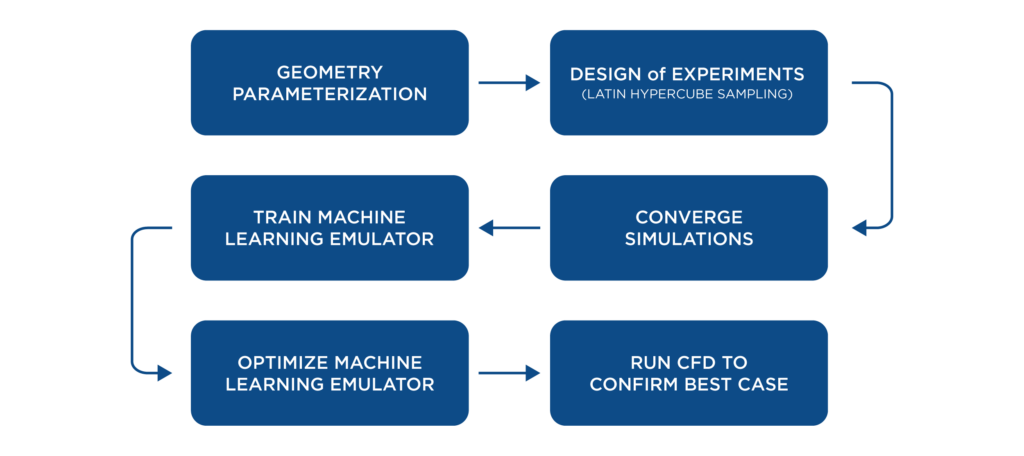

Figure 1 shows a diagram of the optimization process the team undertook. First, they conducted a large design of experiments (DoE) study on CONVERGE Horizon, Convergent Science’s new cloud computing service. The DoE provided insight into how varying different exhaust port geometry parameters affected the exhaust efficiency.

The results of the DoE were then used to train a machine learning (ML) algorithm, which the team used to predict the optimal geometry configuration of the exhaust port. The predicted best case was run in CONVERGE to confirm an increase in efficiency. The results of the study demonstrate that this combination of cutting-edge technologies provides a fast, cost-effective approach for geometry optimization.

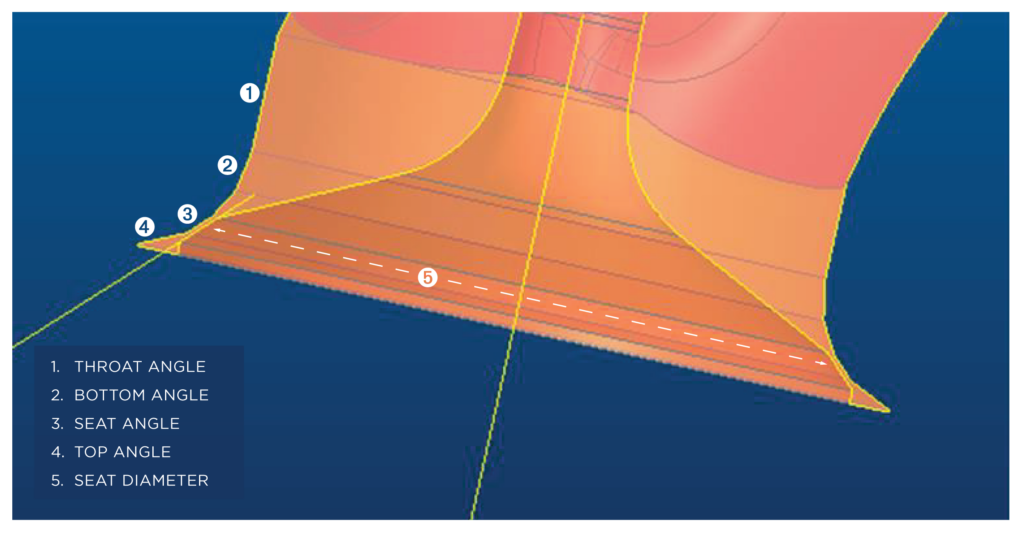

The first step of the DoE was to parameterize the exhaust port geometry. Jacob and his colleagues at Polaris decided on five different parameters to vary: top angle, seat angle, seat diameter, throat angle, and bottom angle (Figure 2). They also specified realistic ranges of values for each parameter based on their current exhaust port geometry.

Trying every possible combination of parameter values would be unrealistic, so the team chose to run 256 cases that spanned the ranges set by Polaris. To select which parameter combinations to test, the team employed Latin hypercube sampling, which produces a quasi-random sample that better captures the underlying data distribution than simple random sampling.

With the parameter values selected, the next step was to generate CAD files of the exhaust port geometry for each case. Creating 256 different geometries can be a daunting task, so the team automated the process using a script in Creo.

To set up the cases for evaluation in CONVERGE, the team once again took advantage of automation. CONVERGE Studio offers a scripting capability that allows users to write custom scripts to automate routine tasks, such as setting up dozens of exhaust port cases. The script automatically flagged the boundaries, set the valve lift, and ran a diagnostic check to ensure the case was ready to go.

“It was exciting to automate most of the approach used in this design study as it saved a lot of time and avoided potential errors if all the case setups were done manually,” says Dan.

Next came the task of running the cases in CONVERGE. DoEs are an ideal use case for high-performance computing, and so the team turned to CONVERGE Horizon. This cloud service for CONVERGE users provides affordable, on-demand access to the latest Oracle Cloud hardware. Arnaud took charge of running the cases concurrently on Oracle Cloud’s bare metal servers. He ran them in two batches on 128 nodes, with one case per node (128 cores/node). Running all 256 cases took less than one day!

“Running CONVERGE on Oracle Cloud provides the benefit of running jobs in parallel and only paying for the usage,” Arnaud says. “Selecting the right hardware configuration gave us the ideal ratio between time and cost. Using the integration with the scheduler, the infrastructure is created and terminated on demand and automatically. Since jobs are independent, multiple regions can be used in case of capacity constraints for extremely large DoEs.”

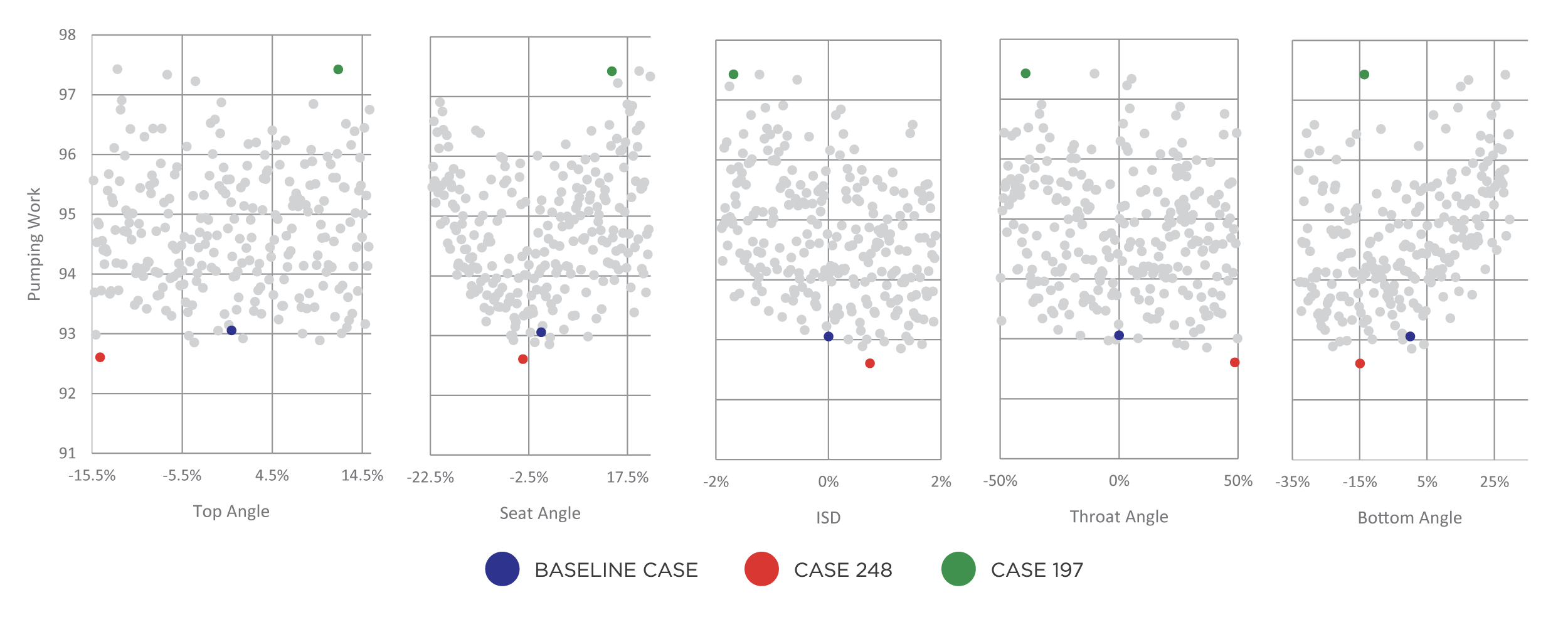

The results of the DoE can be seen in Figure 3. Polaris was looking to minimize the pumping work required by the exhaust process. With that success metric in mind, nine cases performed better than the baseline case (blue dot), i.e., the current exhaust port geometry derived from decades of experiments and manual iterations. The best case (#248) and the worst case (#197) from the DoE are shown in Figure 3 for reference.

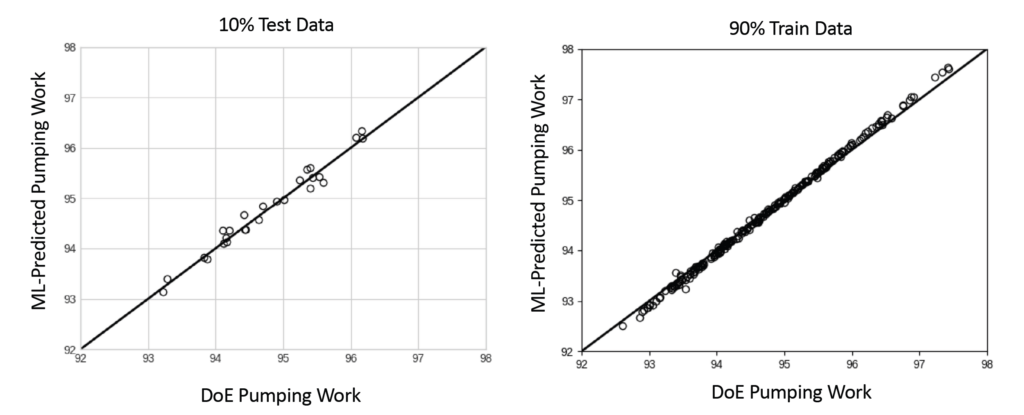

Using the wealth of data from the DoE, Dan trained an ML emulator. 90% of the data was used to train the emulator, and the remaining 10% was used to test the emulator.

“Since you never know what algorithm will best represent the data, we used an ensemble approach to train and rank multiple ML algorithms,” says Dan. As you can see in Figure 4, the ML predictions match well with the simulation data.

The team then used the ML algorithm to predict what combination of parameters would minimize the pumping work. They took the predicted best case and ran it in CONVERGE. While the case did outperform the best case from the DoE, the decrease in pumping work was not as large as predicted.

Dan added this new case back into the ML emulator as a training point and once again had the algorithm predict the best case. The process resulted in only a minimal improvement, suggesting that the team had found an exhaust port geometry configuration that was very near the optimum.

The optimization study resulted in a small (0.5%) but significant improvement in exhaust efficiency to an engine built on decades of accumulated knowledge. This gain was achieved in a matter of days through an optimization process that would have taken months using more traditional methods. Conducting an experimental optimization would have cost on the order of 100 times more than this approach, accounting for both software and hardware costs.

Even using simulations, executing such a large DoE would have taken several months if the simulations were run in serial. CONVERGE Horizon offers competitive prices for top-of-the-line Oracle Cloud hardware, enabling highly scalable and affordable high-performance computing. In addition, the autonomous meshing and scripting capabilities in CONVERGE made it significantly easier to set up such a large number of cases.

“This kind of optimization study has a lot of value in industry,” says Jacob. “Adding high-performance computing and machine learning, we can do this in a really timely and cost-efficient manner. These methods blow traditional optimizations out of the water.”

Polaris will be using the results from this study to inform their upcoming production engine design. Overall, this study demonstrates how you can take advantage of advanced technology to rapidly optimize a system and achieve meaningful, real-world improvements.

Learn more about the process of running a large DoE on Oracle Cloud’s hardware in their blog!